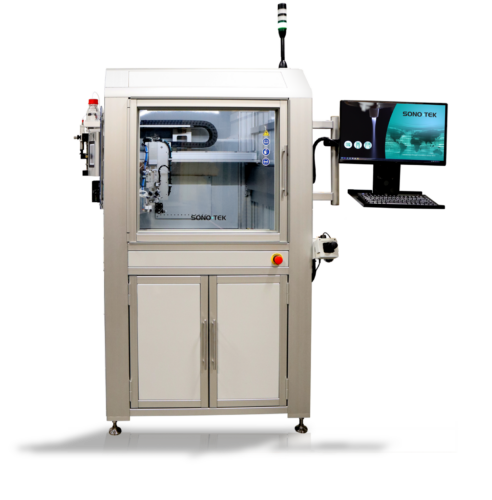

High-performance polyimide polymer layers can be sprayed using ultrasonic spray systems for several potential layer functions in semiconductor manufacturing, including: dielectric layers. passivation layers, stress buffer layers, redistribution layers, and flexible printed circuits. Benefits of Sono-Tek ultrasonic spray systems for polyimide layer deposition include:

- Targeted spray with or without masking

- Uniform thin film layers provide excellent coverage of a variety of wafer sizes and unconventional substrates

- Non-clogging ultrasonic spray requires little maintenance with repeatable performance

- Durable coatings provide mechanical strength, flexibility, and stability across a wide temperature range

- Sono-Tek has extensive expertise spraying polyimides in semiconductor manufacturing applications

Visit https://www.sono-tek.com/ultrasonic-coating/how-ultrasonic-nozzles-work/ for more information about what makes ultrasonic spray advantageous for polyimide coatings.