Uniform, controllable coatings onto Blood Collection Tube (BCT) side walls

Sono-Tek ultrasonic atomizing nozzles have long been considered the premier Blood Collection Tube (BCT) and Syringe Barrel coating technology. The new MedXT series of Blood Collection Tube coating nozzles surpasses the performance of older designs, allowing tube equipment manufacturers to integrate the benefits of next generation precision ultrasonic coating into their manufacturing lines.

Ultrasonic nozzle systems uniformly apply clot activators and anticoagulants including Heparin, EDTA, Silica, and Acid Citrate Dextrose. Specially designed for easy integration into high volume OEM manufacturing lines, the unique slim design allows nozzle placement at standard BCT rack distances, with 10-up configurations processing up to 12,000 tubes per hour. Integration of the MedXT Series with the ECHO generator technology offers superior uniformity and repeatability of coatings. The precise fine tuning capabilities of the ECHO produces tighter drop distribution with smaller droplets for consistent and fast drying dispersions.

MedXT nozzles are available with different tip configurations and in different lengths, dependent upon the diameter and length of your tubes.

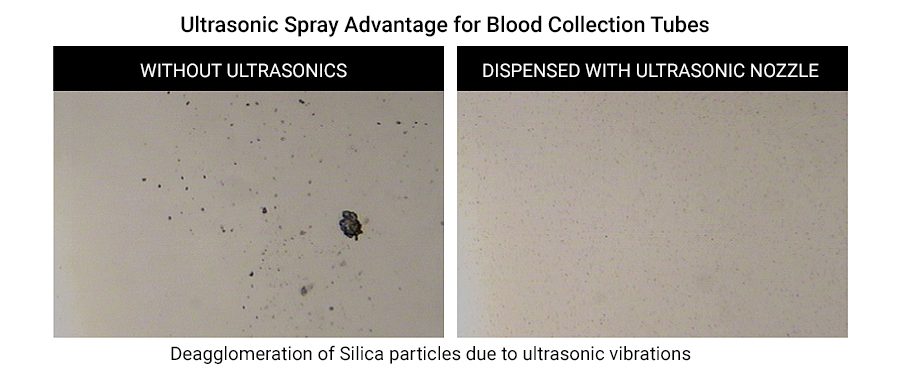

One example of a common blood collection tube ultrasonic coating application is spraying a silica coating to accelerate clotting. Silica slurries are sprayed onto tube side walls, forming uniform thin films of silica particles. Ultrasonic spray is beneficial in this particular application since the ultrasonic vibration of the nozzle breaks apart any silica agglomerates, ensuring a homogeneous coating onto tube walls.

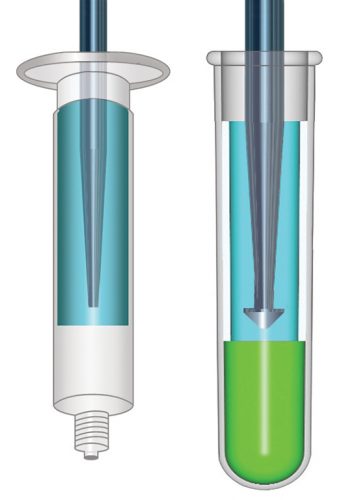

Sono-Tek ultrasonic nozzles also offer the ability to isolate the atomized spray to the walls of a desired bottom coating area of a BCT or Syringe Barrel, instead of coating the complete tube.

MedXT nozzles are available in 3 different configurations:

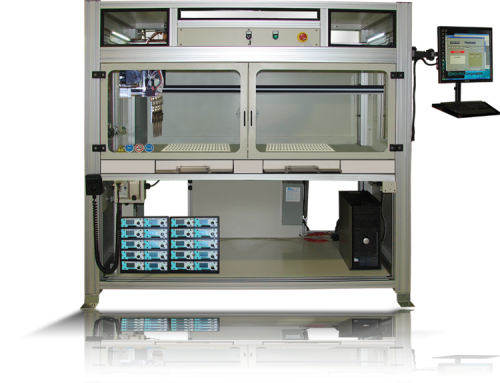

- MedXT Standalone (left) is a fully integrated machine ready to operate as a complete solution and drop into your manufacturing line. Available in configurations for 10 or 20 nozzles.

- MedXT Retrofit (Center) is designed for manufacturers that already have a BCT / Syringe Barrel coating machine and would like to replace existing air spray nozzles with an easy to integrate ultrasonic nozzle package, including liquid delivery and controls.

- MedXT OEM (Right) is designed for BCT and Syringe Barrel machine builders who would like to use Sono-Tek ultrasonic nozzles on the equipment they are building.

These high volume tube coating systems are typically configured with an array of 10 ultrasonic nozzles, and are designed to integrate with manufacturer’s lines. Custom configurations are available. Having over 25 years of experience with syringe barrel and blood collection tube coating processes, Sono-Tek works closely with our customers to provide the best solution for their production needs.

These high volume tube coating systems are typically configured with an array of 10 ultrasonic nozzles, and are designed to integrate with manufacturer’s lines. Custom configurations are available. Having over 25 years of experience with syringe barrel and blood collection tube coating processes, Sono-Tek works closely with our customers to provide the best solution for their production needs.

The Sono-Tek advantage for blood collection tube and syringe barrel coating:

- Unique ultrasonic atomization technology precisely controls droplet size.

- Uniform dispersion of any solids contained in liquid.

- Highly uniform coating on tube walls.

- Manipulation of ultrasonic atomizer accurately in and out of tube inner diameter.

- Fully automated control of electronics.

- Fast track to enter BCT market.

- 25+ years of BCT and syringe coating process experience.

- Self cleaning ultrasonic nozzle requires very little maintenance.

- Ability to control coating area to specific areas on tube walls.