Ultrasonic Spray Coating Machines for Blades and Surgical Tools

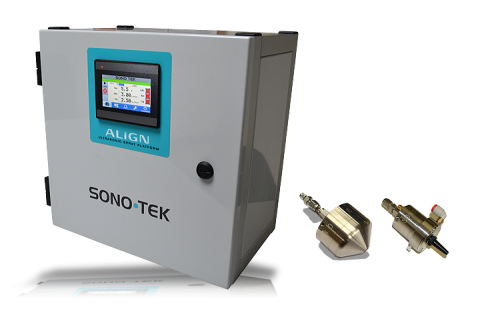

Sono-Tek provides full coating solutions for blade manufacturing coatings, which are easily integrated to existing production lines and will revolutionize your sustainable manufacturing processes.

Sono-Tek provides full coating solutions for blade manufacturing coatings, which are easily integrated to existing production lines and will revolutionize your sustainable manufacturing processes.

Ultrasonic coating systems are used to spray PTFE (Teflon), silicone or other lubricious or protective coatings onto blades and surgical tools to provide a smooth, sharp edge for a precise incision, reducing tissue trauma. Staples for intestinal or vascular anastomosis are also coated using ultrasonic spray.

Advantages of ultrasonic spray compared to pressure spray or other methods include:

- Increased sustainability, up to 80% material savings with no overspray

- Savings on compressed air usage

- Massive downtime reduction, Sono-Tek ultrasonic nozzles are self-cleaning

- Highly uniform coverage with micron-thin films

- Capable of selective, precise area coatings, such as blade edges or fine tweezer tips

- Less curing time

Blade coatings for microtome blades, shaving blades for personal hygiene, medical, and surgical use are extremely well suited to ultrasonic coating processes. Razor edge coatings applied with ultrasonic spray systems are highly repeatable and more uniform than other coating processes, with little to no waste and non-clogging low maintenance spray nozzles.

Visit https://www.sono-tek.com/ultrasonic-coating/ultrasonic-spray-benefits/ and https://www.sono-tek.com/ultrasonic-coating/how-ultrasonic-nozzles-work/ to learn more about what makes ultrasonic spray unique for sustainable manufacturing and surgical tools coatings.

A full line of R&D through high volume coating solutions are available.