Anti-microbial, additive, and barrier coatings onto ready-made food products and food packaging

Sono-Tek ultrasonic food coating systems are most often used for applying thin films of: Antimicrobial coatings onto prepared foods, additive coatings such as flavorings, sweeteners, or nutriceuticals, and barrier coatings onto packaging film and biodegradable containers. In applications where uniform coverage is needed to protect a product or controlled dosage of added ingredients is paramount, ultrasonic coating provides significant process benefits. Ultrasonic spray makes it possible to add very thin layers of small amounts of additives onto prepared products prior to packaging.

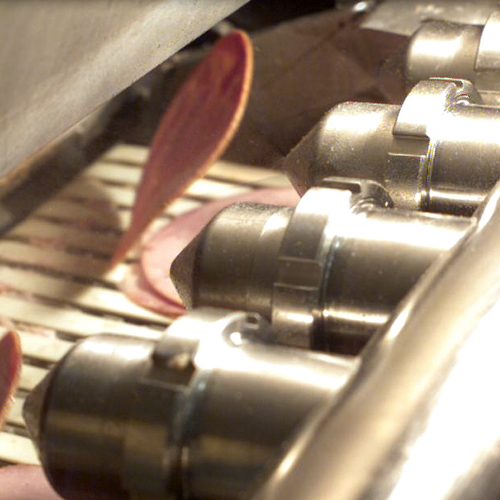

1. Antimicrobial coatings onto deli meat products

Ultrasonic coating systems are ideal for spraying small amounts of antimicrobials onto ready-to-eat food products such as prepared sliced meats to enhance product safety and extend shelf life. Uniform nanolayer antimicrobial solutions enable manufacturers to deposit very thin micron coatings not possible with other deposition methods. Sono-Tek systems are proven to provide 1-2 log reduction in processes where antimicrobial solutions are sprayed directly onto prepared meats during slicing operations, providing an economical alternative to high cost HPP.

Benefits for food safety coatings include tight drop distribution of ultrasonic nozzles compared to pressure spray or other coating methods, which results in more even coverage with thinner layers. This is a major benefit to food manufacturers looking to control ingredient quantities for clean labeling.

2. Additive coatings such as flavorings or sweeteners, nutriceuticals onto prepared foods

2. Additive coatings such as flavorings or sweeteners, nutriceuticals onto prepared foods

Very thin films of sweeteners, flavorings, THC oil and nutriceuticals can be added to products such as cereals granola bars and tea bags, making ultrasonic spray attractive for applications such as reduced sugar or vitamin enhanced products. Little to no overspray of ingredients and repeatable, accurate dosing are major benefits in these coating applications.

3. Barrier coatings for food packaging

Ultrasonic coating systems are used for spraying barrier coating solutions in an effort to reduce or phase out PFAs in food and beverage packaging due to legislation, concerns for environmental contamination and consumer protection from hazardous chemicals. Environmentally friendly packaging often requires barrier coatings for enhanced durability. In addition, thin film barrier coatings onto packaging films enhances shelf life of products without compromising food taste or quality. Dramatic material savings over dip coating and ultra thin uniform films are key benefits of ultrasonic coating for barrier films.

Other applications that benefit from ultrasonic food coating systems include moisturization of prepared products and light oil coatings to prevent food products from sticking to substrates.