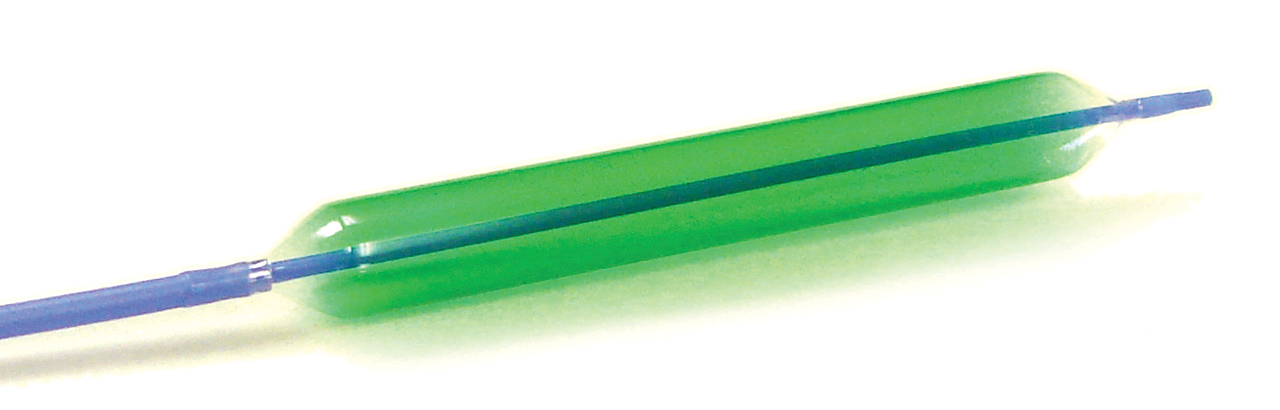

Uniform, durable anti-restenosis drug polymer+plasticizer coatings onto balloon mounted catheters

The MediCoat BCC300 is a balloon catheter coating system designed to coat balloons up to 300 mm in length. A rotating cassette fixture holds one catheter up to 2 meters in length.

The balloon catheter cassette assembly can be removed for coating other medical devices, making the MediCoat BCC a flexible R&D development system for a variety of medical device coatings.

Operating Principle: Balloons are inflated prior to coating. A rotational motor rotates the catheter and balloon 360 degrees while a precision clamping device securely holds the catheter tail in place. The balloon can also be indexed to a user specified degree.

Designed for spraying anti-restenosis solutions containing drug + plasticizers onto catheters mounted with cardiac angioplasty or other drug coated medical balloons. Sono-Tek is the world leader in ultrasonic spraying systems for depositing uniform thin films of anti-restenosis drugs onto implantable devices such a cardiac and peripheral stents. The MediCoat BCC was developed specifically for coating implantable medical balloon catheters. Learn why the unique characteristics of ultrasonic spray produce thinner, more uniform, efficient coatings than other spray deposition methods for precision medical devices. Read an in-depth article titled “Texturing Prospective with Ultrasonically Coated Balloon Catheters”, written by one of our Application Engineers regarding the efficacy of ultrasonic balloon coating and the specific process considerations for optimal coating characteristics using ultrasonic spray.

Ultrasonic Coating Benefits for Balloon Catheters:

- Highly uniform thin film coatings onto cardiac or other balloon catheters for homogenous drug transfer at lesion.

- Dramatic material savings compared to dip coating.

- Reliable, repeatable, controllable balloon catheter coatings.

- Capable of atomizing common combinations of chemistries, including hydrophilic carriers and plasticizers for added coating flexibility.

- Durable coatings with no cracking or peeling ensure proper delivery of the drug at blockage site.

- Ability to spray targeted areas (stripes) on balloon surfaces if preferred rather than coating the entire balloon surface.

- Medical grade gasketing on the catheter holder ensures no damage to the catheter assembly or coiled catheter.