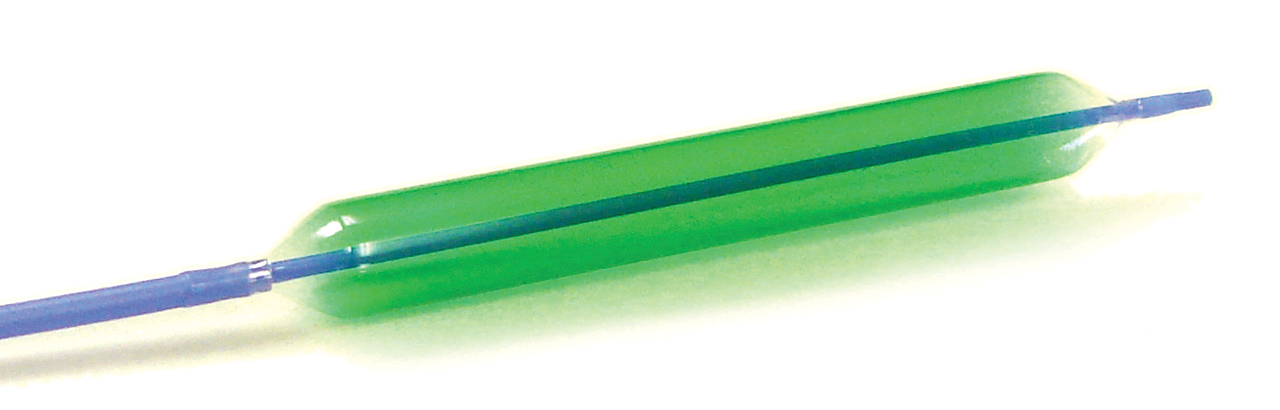

Ultrasonic Coating Systems for Drug-Eluting Balloons (DEB)

Sono-Tek is an industry leader in precision ultrasonic coating equipment for drug-eluting balloons and other implantable medical devices used in cardiology and vascular intervention. The MediCoat BCC balloon catheter coating system is a fully enclosed, user-friendly coating platform designed for high-throughput production of uniform drug and polymer layers on balloon catheter assemblies. The system supports excellent coating uniformity, repeatable film quality, precise balloon length / coated length control, and low material waste for cost-effective medical device manufacturing of DCB and DEB products.

Drug-coated balloon technology has become a critical option in balloon angioplasty and PTCA procedures where drug delivery to the vessel wall helps reduce restenosis, ISR, and the need for repeat stent implantation. These devices complement or compete with drug-eluting stents in PCI strategies, especially in challenging coronary artery lesions, bifurcations, distal vessels, and revascularization cases.

Drug Eluting Balloon Coating Machine for DEB Medical Devices

Drug-coated balloons require tight control of coating thickness, uniformity, and coated length to deliver consistent drug transfer and clinical outcomes. Sono-Tek’s Drug Eluting Balloon Coating Machine, the MediCoat BCC, is purpose-built for DEB / DCB manufacturing, applying antiproliferative drug coating formulations with excipients, polymer carriers, and functional top coat layers onto balloon catheter surfaces using ultrasonic spray. The coating technology produces micron-scale droplets that adhere readily to the balloon, improving drug retention and minimizing overspray waste.

DEB coatings demand uniformity across the balloon surface, repeatable drug load from device to device, compatibility with sensitive drug/polymer chemistries, and precise control of process variables — all while minimizing operator handling to reduce contamination risk. With optimized process recipes, ultrasonic spray coatings can achieve uniformity within ±2 % in demanding medical coating applications.

Typical medical device coatings include:

- Drug coatings deposition on balloon catheter for angioplasty, PTCA, and DCB/DEB products

- Paclitaxel-coated or sirolimus-coated drug-eluting balloon formulations with tailored excipient systems for drug delivery and vessel wall drug transfer

- Polymer/drug matrix layers plus protective or functional top coat chemistries to improve retention and clinical performance

- Specialty drug-eluting or combination therapy coatings where uniformity is critical

For customers looking to coat the catheter portion of a DEB assembly, Sono-Tek also offers dedicated catheter coating machines and coating systems.

Hydrophilic Coating Machine and Catheter Coating Process Options

Many customers use the same balloon catheter coating system architecture to apply hydrophilic coatings for lubricity and improved device functionality. Ultrasonic spray supports low-flow, uniform hydrophilic drug coating deposition without pooling, even on complex balloon catheter assemblies. Recipes can be developed for single-layer or multi-layer coating processes, including hydrophilic top coats or over drug layers, depending on the required medical device performance.

Ultrasonic Spray vs. Dip Coating for Balloon Catheters

Both ultrasonic spray and dip coating have been tested in drug-eluting balloon programs. While dip coating can appear straightforward, manufacturers have consistently moved to ultrasonic spray as the standard method because it provides far better control over critical quality attributes tied to FDA submissions, clinical trial follow-up, and long-term clinical outcomes. Dip coating offers minimal control of coating thickness, and because balloons are repeatedly immersed into an open batch of liquid, there is higher contamination risk and limited ability to maintain consistent liquid quality over time. Drug concentration, excipient balance, particulates, solvent evaporation, and viscosity can drift during a run, affecting drug delivery, retention, and drug transfer to the vessel wall. Dip processes also have very limited ability to control precise start/stop boundaries, making balloon length coverage, coated length, and edge definition harder to repeat — especially for distal or complex coronary targets.

Why ultrasonic coating is chosen as the standard for DEB/DCB production:

- Precise control of coating thickness, drug load, and drug retention

- Closed, low-flow delivery minimizes contamination risk

- Consistent liquid quality throughout the run (no open bath drift)

- Sharp, programmable stop/start boundaries for coated length and balloon length definition

- High transfer efficiency with minimal overspray waste

- Scalable, high-throughput coating process for production lines

Proprietary Balloon Handling and Coated Length Control

The MediCoat BCC incorporates Sono-Tek’s proprietary balloon handling capability, engineered specifically for drug-eluting balloon manufacturing. Precision fixturing with mandrel support protects the catheter while enabling stable 360° balloon rotation. This proprietary handling approach maintains alignment, prevents balloon or catheter damage, and supports programmable coated length patterns with clean, repeatable boundaries — including full-surface coats or striped zones for coronary artery, bifurcation, or peripheral designs.

Modular Coating Platform with UV Curing and Process Add-Ons

The MediCoat BCC is a modular coating platform that can be configured for your exact coating equipment needs across balloon catheter families. Customers often integrate:

- Multi-nozzle heads for higher throughput or layered chemistries

- Inline or staged UV curing and drying to control solvent removal, excipient behavior, and polymer crosslinking

- Post-cure modules to stabilize drug/polymer films and improve retention

- Tooling swaps for different catheter sizes, balloon lengths, and geometries

The modular architecture supports rapid changeover and simplifies scale-up from R&D to validated manufacturing.

High-Throughput Balloon Coating Equipment from R&D to Production

Sono-Tek coating system technology scales from early formulation work through clinical trial build and high-throughput commercial production. High-frequency ultrasonic spray nozzles deliver a soft, low-velocity mist at extremely low flow rates, improving drug transfer efficiency and reducing waste when coating expensive paclitaxel or sirolimus formulations. The result is a user-friendly coating machine that helps medical device teams improve yield while maintaining consistent performance in PCI, PTCA, and revascularization applications where restenosis, thrombosis risk, and ISR reduction are key outcomes.

Talk to an Applications Engineer – Tell us about your DEB/DCB or balloon catheter coating application. Sono-Tek will recommend the proper MediCoat BCC configuration, ultrasonic spray nozzle setup, balloon length / coated length strategy, and UV curing or drying options for your Drug Eluting Balloon Coating Machine and overall medical device drug coating process requirements.