Protective Coatings on Automotive Glass and Functional Coatings for Automotive Manufacturing

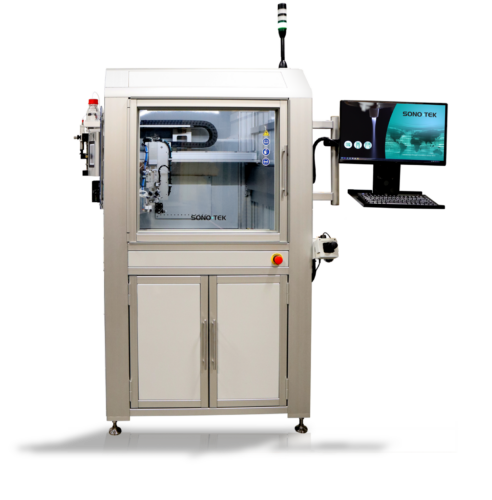

Automotive manufacturers increasingly rely on advanced coating solutions to add new functions, improve durability, and enhance the performance of parts across the vehicle. A major focus area is Protective coatings on automotive glass and Functional Coatings on Automotive Glass, which help windshields and other automotive glass surfaces deliver water repellency, abrasion resistance, optical performance, and long-term clarity. Beyond glass, Sono-Tek ultrasonic coating systems apply high-quality protective and functional coatings on plastics, metals, optics, and fabrics with exceptional uniformity and process control.

Automotive manufacturers increasingly rely on advanced coating solutions to add new functions, improve durability, and enhance the performance of parts across the vehicle. A major focus area is Protective coatings on automotive glass and Functional Coatings on Automotive Glass, which help windshields and other automotive glass surfaces deliver water repellency, abrasion resistance, optical performance, and long-term clarity. Beyond glass, Sono-Tek ultrasonic coating systems apply high-quality protective and functional coatings on plastics, metals, optics, and fabrics with exceptional uniformity and process control.

Ultrasonic spray delivers precisely controllable coating thickness and highly repeatable thin films, enabling high-performance coatings on complex geometries and sensitive substrates while minimizing waste.

Automotive Components Well-Suited for Ultrasonic Spray Coating

Sono-Tek systems are used across the automotive industry to coat:

- Windshield glass and other glass surfaces

- Interior display glass, touch screens, and HUD optics

- Console panels, dashboard components, and molded plastics

- Lenses, headlights, mirror assemblies

- Fabrics, textiles, and interior trim materials

- Exterior parts requiring weather-proofing or surface protection

Whether coating glass products or non-glass components, ultrasonic spray supports consistent film builds and reliable production repeatability.

Automotive Coating Applications (Glass and Non-Glass)

Sono-Tek ultrasonic technology supports a wide range of high-performance automotive coating solutions, including:

Protective Coatings on Automotive Glass

Ultrasonic glass coating enables precise deposition of protective layers on automotive glass to improve durability and reduce abrasion over time. These coatings are engineered for high-quality, uniform coverage across large glass surfaces.

Functional Coatings on Automotive Glass

Functional glass coatings add performance benefits to windshields and interior glass, including:

-

- Hydrophobic water-repellent coatings for enhanced visibility and self-cleaning windshields

- Anti-reflective coatings to reduce glare on interior displays and optical glass

- Oleophobic coatings to reduce fingerprints on interior glass surfaces

- Multi-functional stacks where liquid-based functional layers complement vacuum-deposited inorganic films

These functional coatings help automotive glass deliver critical functions beyond visibility alone.

Hard Coatings for Plastics and Optics

Protective hard coatings (such as Momentive™ SilFORT UVHC5000) are applied to internal console plastics and lenses to increase durability and resistance to wear.

Textile and Fabric Coatings Using Advanced Functional Nano-Materials

Ultrasonic spray is well-suited for applying advanced functional coatings that use nano-materials to enhance textile performance — including water repellency, flame retardancy, anti-soiling, and other surface-modifying effects. Unlike many spray methods that soak or saturate fabrics, ultrasonic technology applies a controlled surface layer coating with uniform coverage while preserving textile breathability, flexibility, and feel. This makes it ideal for scalable production of high-performance automotive interior fabrics.

Weather-Proofing and Protective Exterior Coatings

Coatings for exterior automotive parts improve environmental resistance, UV stability, and long-term durability.

Ultrasonic Spray vs. PVD and Sputtering in Automotive Coatings

Some automotive glass and optical layers — including multi-layer anti-reflective stacks and other dense inorganic films — are produced using sputtering or PVD vacuum deposition. These technologies are well suited for specific thin-film architectures, but they typically rely on slow, batch-style vacuum processing.

Sono-Tek ultrasonic spray provides an attractive alternative or complement when manufacturers want to apply functional coatings from liquid or nano-material formulations without the time and cost constraints of vacuum tools. Because ultrasonic coating systems operate in open air and integrate directly into production lines, they enable:

- In-line, continuous coating rather than vacuum batch cycles

- Precisely controllable thickness on large glass surfaces and complex parts

- Consistent, repeatable coatings when paired with appropriate surface preparation and chemistry

- Efficient application of hydrophobic, self-cleaning, and other liquid-based functional layers

- High-quality coating performance with low material waste

For many automotive programs, vacuum methods handle the inorganic layers they do best, while ultrasonic spray applies high-performance liquid-based layers quickly and efficiently — especially when production throughput and manufacturing flexibility are critical.

Automotive Lubricant Spray for Metal Forming and Automated Production

Sono-Tek ultrasonic coating systems are also well-suited for Automotive Lubricant Spray, especially for aluminum-alloy forming and metal stamping operations. Atomized lubricant coatings protect parts from scoring and cracking and extend tooling life with precise, repeatable film builds.

Sono-Tek ultrasonic coating systems are also well-suited for Automotive Lubricant Spray, especially for aluminum-alloy forming and metal stamping operations. Atomized lubricant coatings protect parts from scoring and cracking and extend tooling life with precise, repeatable film builds.

Benefits include:

- Easy adjustment of flow rate

- Precision spray control for complex patterns

- Drip-free atomized spray with little to no overspray

- No moving parts to wear out

- Very low maintenance

- Material savings of up to 80%

- Improved part quality and forming consistency

Ultrasonic spray is also used for precisely metered mold-injection lubricant and release-type surface coatings on automated molding and casting equipment, delivering a uniform surface layer with controllable thickness while minimizing waste.

Clean, Efficient, High-Performance Automotive Coating Solutions

Sono-Tek ultrasonic spray is recognized as a green, scalable coating solution for automotive manufacturing. Across glass products and other automotive surfaces, ultrasonic coating systems deliver:

- High-quality, repeatable thin films with controllable thickness

- Long-term durability for demanding automotive environments

- Reduced material consumption and cleaner production

- Efficient integration into high-volume manufacturing

Whether applying protective coatings on automotive glass, functional coatings on automotive glass, nano-material surface coatings to textiles, or automotive lubricant spray to stamped metal parts, Sono-Tek provides high-performance automotive coating systems built for production reliability.

Sono-Tek ultrasonic coating systems are well known for being green technology coating systems in high volume manufacturing, with significant savings and environmental benefits with seamless integration onto production lines.

In addition to lubrication coating systems, Sono-Tek provides mold release agent coating systems for reduced defects in the manufacture of molded parts.