Uniform anti-restenosis drug coatings onto cardiac, peripheral, biodegradable, and other implantable stents

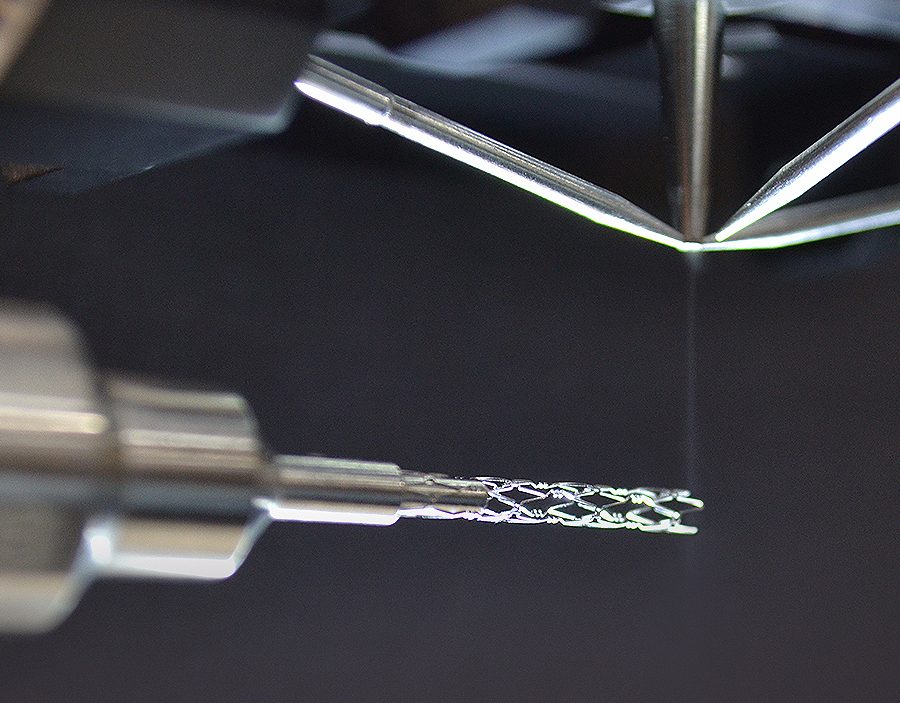

Sono-Tek stent coating machines are considered the industry standard and are used by most of the largest DES manufacturers in the world. Our ultrasonic coating systems have been used to spray anti-restenosis drug eluting polymer solutions onto implantable stents for decades. We have expertise in spraying hundreds of different medical grade polymer chemistries. Ultrasonic spray nozzles are advantageous in penetrating complex stent geometries, ensuring full coverage of all strut surfaces without webbing. The soft atomized spray adheres well to surfaces and coating morphology characteristics can be adjusted by modifying process parameters. Pressure spray nozzles and air atomizers are not able to apply coatings as uniformly as Sono-Tek ultrasonic coating systems. Coatings applied using ultrasonics are much thinner than can be achieved with dip coating, saving spray material while avoiding webbing. Since ultrasonic nozzles are non-clogging devices, spray quality is not compromised over time due to gradual clogging as seen in pressure nozzle processes.

Sono-Tek stent coating machines are considered the industry standard and are used by most of the largest DES manufacturers in the world. Our ultrasonic coating systems have been used to spray anti-restenosis drug eluting polymer solutions onto implantable stents for decades. We have expertise in spraying hundreds of different medical grade polymer chemistries. Ultrasonic spray nozzles are advantageous in penetrating complex stent geometries, ensuring full coverage of all strut surfaces without webbing. The soft atomized spray adheres well to surfaces and coating morphology characteristics can be adjusted by modifying process parameters. Pressure spray nozzles and air atomizers are not able to apply coatings as uniformly as Sono-Tek ultrasonic coating systems. Coatings applied using ultrasonics are much thinner than can be achieved with dip coating, saving spray material while avoiding webbing. Since ultrasonic nozzles are non-clogging devices, spray quality is not compromised over time due to gradual clogging as seen in pressure nozzle processes.

Advantages of Ultrasonic Spray for Stent Coatings:

- Highly controllable and repeatable spray.

- Non-clogging ultrasonic technology.

- Ability to spray at flow rates in the microliter per hour range.

- Droplet sizes as small as 9 microns (with organic solvents) with very tight drop distributions.

- Low velocity spray adheres to stents without bounceback or overspray.

- Proven process for coating implantable stents & other precision medical devices.

- Highly durable coatings will not flake or peel.

- Over a decade of experience coating with hundreds of systems in operation.

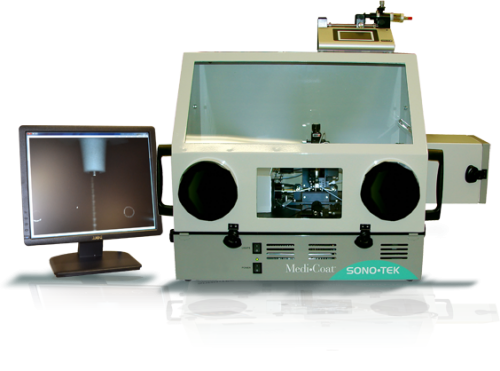

Sono-Tek can provide validation criteria for stent coating processes using our MediCoat systems, including qualification documentation for installation, operation, performance and maintenance qualification of MediCoat ultrasonic coating systems.

In addition, our full in-house coating laboratory enables customers to simulate process testing using their stents to help improve and establish process criteria. Our laboratory technicians and engineers have extensive experience coating different types of stents.

MediCoat DES

Good people to work with. Very easy to use and works really well.Specialized Vascular Tech – CA USA

Our MediCoat technology provides organizations such as the US FDA, as well as many global stent manufacturers, with the ability to test and produce high quality repeatable polymer and drug/polymer coatings. As the industry’s leader in ultrasonic stent coating for over a decade, Sono-Tek’s stent coating technology is used by 90% of the research and manufacturing institutions in the stent coating market worldwide, with over 600 systems in operation.

Click here for a technical paper discussing drug-eluting coatings using ultrasonic spray technology: Application of Quality by Design (QbD) Approach to Ultrasonic Spray Coating of Drug-Eluting Stents.

Types of Stents Coated Using Ultrasonic Spray (Metal or Bioabsorbable Materials):

- Arterial

- Peripheral

- Sinus

- Bifurcated

- Bare Metal

- Biodegradable

- Stent Grafts