Stent Coating Systems

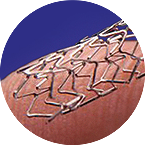

Sono-Tek is the industry leader in ultrasonic Stent Coating System technology for coronary stents and other implantable medical devices. For decades, our systems have set the standard for drug-eluting stent coating, and today a large share of commercial DES and bare metal stents are produced using Sono-Tek equipment. Our non-contact ultrasonic coating process delivers highly uniform drug and polymer layers with repeatable adhesion, controlled coating thickness, and minimal overspray — all while eliminating webbing between stent struts. This “no webbing” capability is a key attribute for maintaining open geometry, consistent drug delivery, and reliable clinical performance in cardiology applications.

Stent Drug Coating System for Controlled Drug Delivery and Release

Drug-eluting stents rely on consistent drug delivery to the coronary artery, with predictable drug release profiles over time. Sono-Tek’s Stent Drug Coating System applies antiproliferative drug formulations, polymer carriers, and topcoat layers precisely onto complex stent geometries using programmable motion and closed-loop process control. Ultrasonic atomization produces micron-scale droplets that coat struts evenly without pooling or bridging, supporting stable drug release, high biocompatibility, and strong clinical outcomes.

Coatings are most commonly applied to bare metal stents, and Sono-Tek systems are also used for bioabsorbable stents where uniform drug/polymer coverage and gentle, non-contact deposition are critical.

Typical coating applications include:

-

- DES drug/polymer matrix layers for controlled drug delivery

- Topcoat or diffusion-barrier layers to tune drug release

- Coatings for bare metal stents and bioabsorbable stents

- Specialty drugs and polymers for unique cardiology programs

DES Coating Machine Advantages and No Webbing Performance

Traditional stent coating methods often struggle with coating uniformity on intricate struts, excessive material waste, and variability in drug loading. They can also create webbing or unintended bridges between struts, which can impact performance. Sono-Tek DES Coating Machine technology avoids these issues by enabling:

-

-

- Uniform coating around struts and across the full stent surface

- Precise control of drug load and coating thickness for consistent drug release

- Strong, repeatable adhesion on bare metal and polymer-primed surfaces

- No webbing between struts, preserving stent geometry and lumen openness

- Lower waste of high-value drug formulations

- Programmable recipes that repeat reliably for clinical trials and validated manufacturing

-

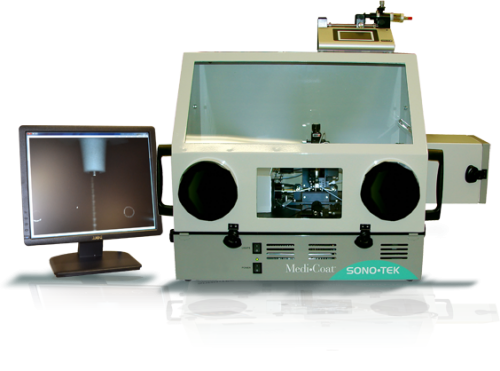

Complete MediCoat Stent Coating System Product Line

Sono-Tek offers multiple stent coating system platforms to match coronary, peripheral, and specialty stent programs:

-

-

- MediCoat DES systems for coronary stents and drug-eluting stents

- MediCoat PSI platforms for peripheral stents and larger-diameter implantable devices

- Custom stent coating machines engineered for unique stent types, geometries, and coating requirements

- High-volume stent coating platforms with multi-nozzle configurations and automation for production-scale throughput

-

This breadth allows customers to develop coatings on one platform and scale directly to high-volume stent coating machines while maintaining the same ultrasonic coating technology and process recipes.

MediCoat DES 3000/4000 and High-Volume Platforms

Sono-Tek’s MediCoat DES 3000/4000 systems remain a core DES Coating Machine family for development and production-scale coating of coronary stents. These systems combine high-frequency ultrasonic spray nozzles with precision stent fixturing and automated motion control to deliver:

-

-

- Consistent coating thickness from nanolayers through multi-micron builds

- Uniform drug/polymer coverage without pooling or webbing

- Flexible recipe development for new drugs, polymers, and drug release targets

- Scalable configurations for clinical trials through high-volume manufacturing

-

For manufacturers requiring maximum throughput, Sono-Tek also provides high-volume stent coating platforms with automated handling and multi-nozzle architectures tailored to specific production needs.

Biocompatibility, Adhesion, and Quality for Implantable Devices

Coating performance depends on a stable interface between the drug/polymer layer and the stent substrate. Ultrasonic spray supports excellent adhesion and consistent layer morphology, reducing the risk of cracking, flaking, or particulate generation. This contributes to biocompatibility and reliable long-term drug delivery in coronary artery and peripheral vascular environments.

From Clinical Trials to High-Volume Stent Manufacturing

Sono-Tek stent coating systems scale from early clinical trial builds to validated commercial DES production. Customers choose Sono-Tek because our Stent Coating System technology delivers no-webbing coatings, tight drug-loading control, high repeatability, and proven production scalability — backed by the largest installed base of stent coating machines in the industry.

For large-scale, automated manufacturing environments,

For large-scale, automated manufacturing environments,

Talk to an Applications Engineer – Tell us about your coronary or peripheral stent coating application. Sono-Tek will recommend the right Stent Coating System — including MediCoat DES 3000/4000, MediCoat PSI, custom stent coating machines, or high-volume stent coating platforms — along with nozzle selection, drug/polymer strategy, and process parameters to achieve your targets for drug delivery, drug release, adhesion, biocompatibility, and production throughput.