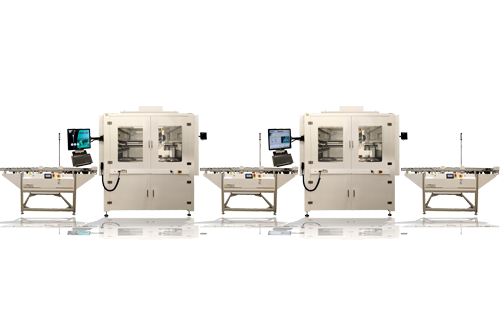

Sono-Tek designs and builds high-volume, automated inline coating equipment for precision coating applications across industries including medical device components, electronics, glass, textile, and automotive manufacturing. These inline coating systems are engineered for continuous, repeatable operation with full process control and real-time performance feedback.

Our custom coating machines are developed to meet the specific requirements of high-throughput production lines, combining scalable coating technology, intelligent motion control, and advanced substrate handling. Whether optimizing a coating process for electronic packages, implantable medical devices and films, high-tech glass substrates, or large-format panels, Sono-Tek’s inline coating systems deliver high-quality, high-precision results with minimal waste.

Engineered for Inline Performance and Flexibility

Each inline coating system is built to integrate seamlessly into existing production lines or operate as a standalone coating line. Sono-Tek systems can include fully automated substrate feed and positioning modules, dual-sided coating configurations, precision ultrasonic dispensing, and controlled atomization droplet size with variable-width spray coater heads for even the most demanding applications.

Typical inline configurations may include:

• Customized substrate handling and motion control fixtures

• Pre-heat and curing zones for precise temperature management

• Plasma or corona surface treatment for optimal coating adhesion

• Heat or vacuum lift plates and dual-sided flip modules

• Real-time process control and monitoring with integrated control systems

• Optional bar code readers and automated substrate feed solutions

• Palette stacking and retrieval modules for uninterrupted throughput

These systems are designed to optimize coating efficiency, enhance throughput, and deliver consistent layer uniformity for both simple and complex coating applications.

Scalable High-Volume Coating Technology

Sono-Tek’s high-volume coating equipment is fully scalable, accommodating anything from small medical components to full-panel processing for oversize substrates such as one-meter-plus glass or membrane panels. Each system is configured for maximum flexibility, supporting single-pass or multi-pass operation within the same coating line.

Our inline coating systems can incorporate:

• Custom coating machines designed for medical, microelectronic, and industrial components

• Specialized coating solutions for medical device, aerospace, and automotive applications

• Configurable platforms that integrate multiple nozzles or heads for expanded throughput

• Optional integration with vision alignment, control system feedback loops, and real-time process optimization

This level of adaptability allows Sono-Tek customers to maintain high-quality output while minimizing changeover time and increasing yield.

Intelligent Automation and Process Optimization

Every inline coating system from Sono-Tek is engineered for full automation and repeatability. Intelligent process control provides continuous feedback on flow rate, temperature, and deposition, allowing users to fine-tune performance for maximum efficiency and high-precision coating results.

Systems can be operated through Sono-Tek’s intuitive HMI or configured to run on a customer-specified PLC, such as Allen-Bradley, Beckhoff, or Siemens platforms. Our automation team works directly with customers to integrate these controls into larger automated coating equipment architectures for synchronized operation across the production floor.

Applications and Industries

Sono-Tek’s inline coating equipment is used in a wide variety of high-volume coating environments, including:

• Medical device components such as catheters, stents, guidewires, diagnostic strips, and medical films

• Automotive parts, sensors, and optical components

• PCB and electronics manufacturing for protective, conformal, and conductive coatings

• Glass and polymer substrates for barrier, hydrophobic, or nano-functional layers

• Textile and industrial films requiring uniform, scalable coating coverage

• Energy and display technologies where throughput and layer uniformity are critical

Each installation is supported by Sono-Tek’s application engineering team to ensure the coating process is fully optimized for fluid properties, substrate materials, and required film performance.

Custom Inline Coating Solutions

Sono-Tek’s application engineering and forward-deployed engineering teams collaborate closely with each customer to develop custom coating solutions that meet precise performance and production targets. From compact single-lane systems to multi-lane inline coating lines with automated material handling, Sono-Tek delivers scalable, high-volume coating equipment that grows with your manufacturing needs.

Visit Custom Engineered Coating Systems for more information, or learn how ultrasonic nozzles create the foundation for Sono-Tek’s non-contact, high-precision coating technology.

Contact Sono-Tek today to discuss an automated inline coating system tailored for your next high-volume coating or medical device component application.