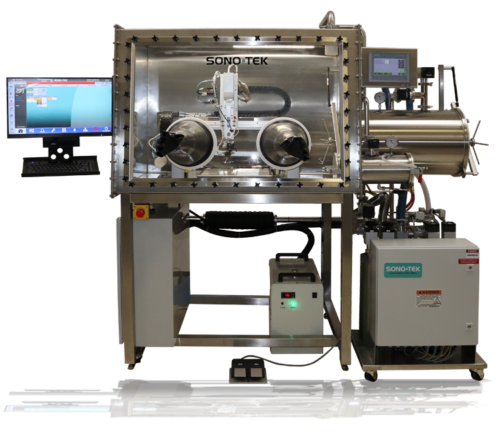

A glovebox enclosure fully integrated with an ExactaCoat OP3 XYZ motion programmable coating system. The ExactaCoat Inert allows for coatings that require tight atmospheric control or for the safety required by some applications.

Visit How Ultrasonic Nozzles Work to learn more about the unique capabilities of ultrasonic spray.

ExactaCoat Inert Antechambers ExteriorInteriorInterior Antechambers OpenExactaCoat Tabletop Coating System

Alternative Energy & Nanomaterials

Basic Specifications

| Dimensions: 198 cm W x 183 cm H x 91 cm D (37.2” W x 31.2” H x 32.7” D) |

| Work Area*: 420 mm x 480 mm x 80 mm (16.5” x 18.9” x 3.15”) *NOTE: Work area may be reduced depending upon system configuration |

| Control: Windows-based touch screen |

| Power Requirements: 120V, 220V, +/-10%, 50-60Hz |

| Air: 551.6 kPa (80 PSI) dry unlubricated air |

| Motors: Brushless DC servo |

| Certification: CE |

| Ultrasonic Nozzle Designs:: AccuMist, Impact, Vortex, MicroMist, or Propel |

System Options

| Liquid Delivery: Common Liquid Delivery: Syringe pump (standard, Sonic or stirring), gantry mounted syringe pump, MicroFlow, SonoFlow Fusion, HyperFlow catalyst pump |

| Common Options*: Heat and/or Vacuum Plate: 150, 250C heat/vac or 500C heat |