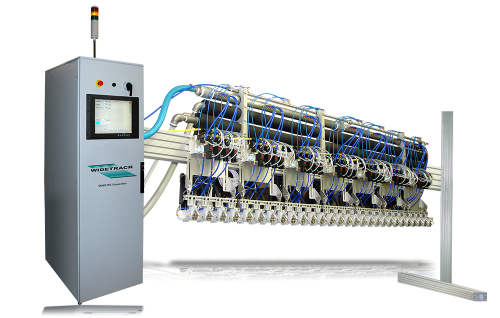

The Industrial WideTrack Impact is a precision-engineered ultrasonic wide-area spray machine designed for creating thin, uniform coatings across a wide range of substrates. It combines Sono-Tek’s proven ultrasonic atomization technology with a unique flat-jet air deflector that produces a highly controllable fan-shaped spray pattern.

Each Impact head creates a coating area up to 15 inches wide, and multiple heads can be combined for unlimited coating width. This scalable design allows manufacturers to coat flexible webs, panels, or films in both roll-to-roll and inline configurations. The Impact system delivers excellent film uniformity with far less overspray than conventional pressure or air atomizing coaters—commonly achieving up to 90% material savings.

Unlike gravure coating and other contact-based methods, the Impact system applies coatings using a completely non-contact ultrasonic process, ensuring smooth, defect-free films even on delicate substrates.

Precision Coating Control and Integration

The WideTrack Impact provides precise control over flow rate, spray velocity, and droplet size for consistent coating thickness and edge definition. Sono-Tek’s ultrasonic atomization process generates fine, low-velocity droplets that deposit evenly on polymer, textile, or glass substrates without clogging or excessive buildup.

The system’s advanced control interface offers full recipe management, data logging, and automated parameter adjustment. Sono-Tek can supply systems with its standard control platform or integrate customer-specified PLCs, including Allen-Bradley, Beckhoff, or Siemens systems, to match existing factory automation. The Impact can also be incorporated into Sono-Tek’s custom roll-to-roll coating systems featuring unwind, rewind, and inline drying for turnkey process solutions.

Key Advantages

• Thin, uniform coating layers with consistent film thickness

• Up to 90% reduction in overspray and coating waste compared to pressure spray systems

• Non-clogging ultrasonic nozzles for continuous, maintenance-free operation

• Scalable modular design for coating widths from a few inches to several meters

• Single- or dual-sided coating capability

• Adjustable fan pattern for selective or full-area coating applications

• Compatible with custom roll coating or inline substrate handling systems

• Optional customer-requested PLC control integration

Thin-Film and Polymer Coating Applications

The WideTrack Impact system is used worldwide for applying thin functional layers and nano-coatings in industrial, medical, and advanced materials manufacturing. Common coating applications include:

• Polymer and nano-composite films for flexible electronics or barrier coatings

• Antimicrobial, hydrophobic, and conductive coatings for medical and technical textiles

• Flame retardant, softener, and fragrance layers for performance fabrics

• Moisture management and repellency coatings for activewear and industrial fabrics

• Thin protective or functional coatings on films, foils, and glass substrates

Designed for High-Performance Coating Applications

The Impact coater’s controllable air deflector directs the ultrasonic spray into a stable fan pattern for precise film formation. Its scalable design, low material usage, and integration flexibility make it an ideal solution for advanced coating applications requiring tight process control and repeatability.

Systems can be configured for spray-up, spray-down, or horizontal orientations, depending on substrate handling requirements. Sono-Tek engineers work closely with each customer to match nozzle spacing, air shaping, and line speed to specific coating goals.

Example System Configurations

Each Impact head produces a coating pattern up to 15 inches wide, and multiple heads can be combined for any required total width.

Typical specifications per nozzle assembly:

• Coating width: up to 15 inches per assembly (expandable to unlimited width)

• Typical flow rate range: 2–200 mL/min depending on pump system

• Typical Deposition uniformity: ±10%; repeatability: ±2%

• Power requirements: 110–240 VAC, single phase

• Air supply: clean, oil-free air, 70–150 psi

Energy-Efficient and Environmentally Responsible

Sono-Tek’s ultrasonic spray systems are designed to minimize energy use, waste, and chemical consumption. The low-velocity, targeted spray pattern reduces overspray and eliminates the need for costly exhaust or recovery systems, creating a cleaner and more efficient coating process.

Request a Custom Configuration

Each WideTrack Impact system is configured for the customer’s coating material, substrate, and production environment. Sono-Tek can provide standalone or integrated roll-to-roll configurations, complete with unwind and rewind modules, tension control, and inline drying.

Contact Sono-Tek today to discuss a customized WideTrack Impact system for your thin-film or polymer coating application.

Glass & Industrial

Basic Specifications

| Spray Width: custom widths up to 3.3m (130”) configuration up to 28 impact spray assemblies |

| Control: Windows-based industrial embedded controller (modern PLC) with 19” touch screen HMI, NEMA 12 cabinet cooled by integrated AC |

| Power Requirements: 220 VAC, 25-50A (depending on configuration) L,L, N, G 50/60 Hz (base model) |

| Air: 621-1034 kPa (90-150 PSI) @ 3000LPM (110 CFM) max, 500LPM (~20CFM) typical. Clean, dry and oil-free |

| Certification: CE |

| Ultrasonic Nozzle Designs: Impact |

System Options

| : Up to 28 spray assemblies, insulated liquid lines to maintain liquid temperatures when required |