Implantable Membrane Coating Systems for Uniform, Bioactive Thin Film Coatings

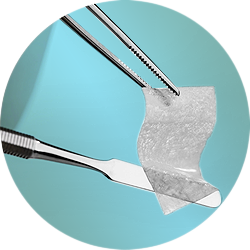

Sono-Tek ultrasonic spray technology delivers precision thin film coating for implants, enabling highly uniform, repeatable application of bioactive, biocompatible, and drug-eluting membrane coatings. Medical device manufacturers worldwide rely on Sono-Tek systems for applying controlled-thickness thin films onto implantable membranes, meshes, and scaffolds made from advanced biomaterials.

Sono-Tek ultrasonic spray technology delivers precision thin film coating for implants, enabling highly uniform, repeatable application of bioactive, biocompatible, and drug-eluting membrane coatings. Medical device manufacturers worldwide rely on Sono-Tek systems for applying controlled-thickness thin films onto implantable membranes, meshes, and scaffolds made from advanced biomaterials.

These coatings support targeted drug delivery, improved in vivo performance, enhanced biocompatibility, reduced stenosis, and greater long-term durability. From PLGA-based bioactive coatings to functional thin film deposition onto porous substrates, our systems provide unmatched precision across applications that traditional dip-coating or pressure-spray methods cannot handle.

Ultrasonic Precision for Porous, Complex, and Irregular Membranes

Sono-Tek’s ultrasonic atomization technology creates a soft, low-velocity spray ideal for coating porous, flexible, and irregular medical implants. This enables uniform thin film coatings without clogging or pooling, preserving membrane structure and mechanical integrity.

By controlling droplet size, flow rate, and coating morphology, our systems allow device developers to precisely tune:

- Coating thickness

- Release profiles for drug-eluting membrane coatings

- Surface properties that influence osseointegration, healing, and corrosion resistance

This level of control is ideal for coatings containing biologically active materials such as PLGA, growth factors, antimicrobials, paclitaxel, or other components used to improve in vivo performance or mitigate restenosis.

Typical Applications for Implantable and Bioactive Membrane Coatings

Bioresorbable and Permanent Surgical Meshes

Soft-tissue reinforcement meshes benefit from conformal biocompatible membrane coating layers that reduce tissue adhesion, enhance healing, or add antimicrobial and lubricious properties. Thin film deposition ensures even coverage across open-cell and irregular structures.

Surgical Barrier and Anti-Adhesion Membranes

Ultrasonic spray coating provides controlled-thickness bioresorbable layers that regulate degradation, reduce inflammation, and improve biomedical compatibility. Ideal for membranes intended for post-operative adhesion prevention.

Vascular Graft and Stent-Graft Membranes

Ultrasonic spray enables uniform deposition of drug-polymer thin films, hydrophilic coatings, or bioactive layers onto polymeric or textile graft membranes. These coatings can improve endothelialization, reduce stenosis, and support localized drug delivery.

Although this page focuses on membrane coatings, Sono-Tek also provides complete solutions for drug-eluting stent (DES) applications—including paclitaxel and sirolimus coating systems. See our dedicated DES page for stainless steel and cobalt-chromium stent coatings.

Regenerative and Tissue-Engineering Scaffolds

Porous collagen or polymer scaffolds can be coated with biodegradable polymers such as PLGA, bioactive thin films, or growth factors to guide tissue growth, control degradation, and promote integration.

Dental and Orthopedic Barrier Membranes

Membranes used for guided bone and tissue regeneration benefit from biocompatible membrane coatings that support osseointegration, enhance healing, and improve implant interface performance.

Benefits of Sono-Tek Ultrasonic Thin Film Deposition

- Uniform, conformal thin film coatings on porous, irregular, or flexible substrates

- Highly precise control of thickness, drug loading, morphology, and surface functionalization

- Non-clogging, low-velocity spray prevents pore blockage and maintains membrane integrity

- Compatible with solvent-based, water-based, and biologically active formulations

- Supports bioactive, lubricious, antimicrobial, or drug-eluting membrane coating requirements

- Scalable from R&D through fully validated medical production environments

- Applicable to polymer, textile, and even stainless steel reinforcement components

- Process Development, Validation, and Biomedical Expertise

Sono-Tek’s in-house medical coating laboratory assists with process development using customer-supplied materials and biomaterials. Our engineers help refine coating parameters for uniformity, drug release behavior, corrosion resistance, durability, and long-term in vivo performance.

With decades of experience in biomedical thin film coating and systems installed worldwide, Sono-Tek continues to set the standard for precision thin film coating for implants, implantable membranes, and other advanced medical devices.

Contact Sono-Tek’s Medical Coating Team to begin your project.