Ultrasonic Technology for Vacuum Vapor Deposition Applications

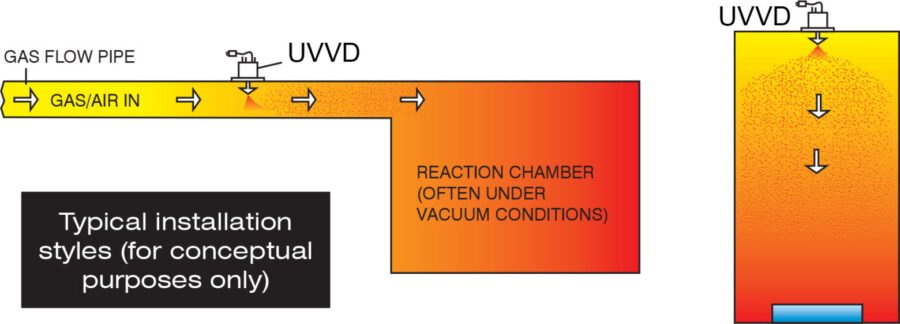

Sono-Tek UVVD Series ultrasonic nozzle systems are designed to be integrated onto vacuum chambers, provided by the original equipment manufacturer (OEM). These platforms enable use of an Ultrasonic Nozzle in Vacuum for specialized deposition environments and are proven for integration onto vacuum-enclosed systems used in applications such as Polymer Vapor Deposition (PVD) and Metal Organic Chemical Vapor Deposition (MOCVD). The characteristic low-velocity ultrasonic spray and Atomization in Vacuum created by the UVVD Series produces a vapor cloud with a tight droplet size distribution and controlled droplet size based upon high-frequency operation. Because ultrasonic nozzles operate by converting high frequency sound waves into mechanical vibration, liquid that contacts the nozzle surface is atomized without the addition of air or carrier gas, so vacuum integrity is maintained during vapor deposition. Equipped with a proprietary flow restriction device and choice of KF or CF vacuum flange, integration of the UVVD system is ideal for OEM vacuum deposition coating system manufacturers (typical vacuum range is 0.1 – 1 torr; 13 – 133 pascal; 0.13 – 1.3 millibar).

The ECHO generator technology integrated into UVVD Series ultrasonic spray coating systems provides the electrical energy required for atomization and includes an advanced load-leveling feature. This automatically adjusts to varying vacuum conditions and liquid flow rates, maintaining stable spray patterns and uniform thin film deposition on substrates such as wafers and large-area parts during vacuum deposition processes.

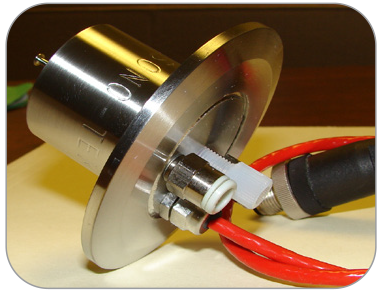

UVVD Series ultrasonic nozzles are equipped for high-temperature vacuum environments and include cooling capability and temperature monitoring to ensure proper heat protection and consistent atomization performance.

Benefits for vacuum chamber applications include:

- Load-leveling designed electronics

- High-temperature protection and monitoring

- Unique liquid flow restriction design for vacuum conditions

- Atomization is created without air or gas, maintaining vacuum integrity

Learn more about what makes ultrasonic nozzles unique and their benefits in spray chamber applications.