Lens Coating System for High-Quality Thin-Film Optical Coatings

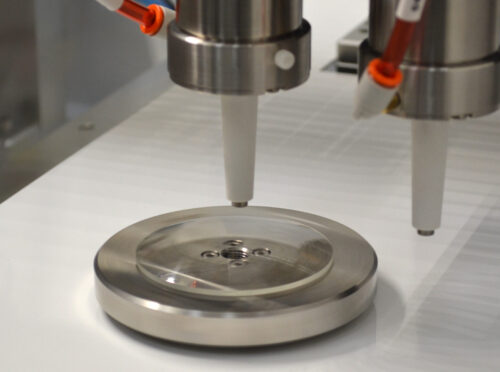

Sono-Tek ultrasonic spray technology provides a precise, repeatable Lens Coating System for applying functional and aesthetic optical coating layers to a wide range of lenses, mirrors, and other optical components. Ultrasonic atomization enables uniform thin film deposition on curved or shaped substrates with controllable thickness and minimal material waste, supporting high-quality manufacturing across both R&D and production environments.

Sono-Tek ultrasonic spray technology provides a precise, repeatable Lens Coating System for applying functional and aesthetic optical coating layers to a wide range of lenses, mirrors, and other optical components. Ultrasonic atomization enables uniform thin film deposition on curved or shaped substrates with controllable thickness and minimal material waste, supporting high-quality manufacturing across both R&D and production environments.

By operating in open air and integrating directly into production lines, ultrasonic spray can serve as a cost-effective alternative or complement to traditional coating methods such as dip coating, spin coating, or vacuum-based sputter processes in a vacuum chamber—especially when coating formulations are liquid-borne.

Optical Coating Applications for Lenses and Mirrors

Sono-Tek coating systems support many optical coating applications where performance, durability, and repeatability matter. Ultrasonic spray is used to deposit single-layer and multi-layer coatings, including:

- Anti-fingerprint / anti-smudge coatings

- Hard coating and scratch-resistant coatings (SRC)

- Anti-glare coatings

- Anti-fog coatings

- UV-blocking coatings

- Tints and electrochromic coatings

- Liquid-applied mirror coatings and other functional surface layers

These coatings can be applied to uncoated optical parts with consistent results, helping manufacturers achieve high-performance surfaces without overusing expensive solutions.

Photoresist Deposition on Lenses and Mirrors for Patterned Optics

Sono-Tek ultrasonic spray is used for Photoresist Deposition on Lenses and mirrors, enabling controlled photoresist thin films on optical substrates of virtually any scale — from very small precision lenses and micro-optics to large-area lenses and mirrors. This supports patterned or selective coating steps in advanced optical manufacturing, where uniform resist thickness is required before downstream exposure and development.

Ultrasonic spray photoresist deposition provides:

- Repeatable thin-film photoresist coverage on small or large curved surfaces

- Controllable thickness for consistent patterning results

- Low-stress deposition suitable for sensitive optical components

- Efficient material use for cost-effective production

Lens Materials and Substrates Supported

Sono-Tek lens coating systems are compatible with many common optical substrates, including:

- Polycarbonate (lightweight, durable plastic)

- Standard optical plastics

- Trivex (impact resistant, thin, lightweight)

- High-index plastics

- Glass (highest optical clarity and scratch resistance)

- Polarized lens constructions

This flexibility allows one coating system to support multiple optical product types and manufacturing processes.

Optical Components and Markets Served

In addition to eyewear lenses, Sono-Tek ultrasonic spray coating is widely applicable to:

- Precision optic lenses

- Microscope lenses

- Telescope and binocular lenses

- Camera and imaging lenses

- Scope lenses and specialty optics

- Industrial and scientific optical components

Eyewear Coating Machine Capability (When Needed)

For customers producing ophthalmic or sunglass lenses, Sono-Tek systems can also be configured as an Eyewear Coating Machine to apply functional coatings on high-curvature lens geometries, including bifocals and multi-zone designs. The same thin-film precision used in industrial optics translates directly to these applications.

Thin-Film Coating with Production Throughput

Ultrasonic spray enables high-performance optical coating deposition without the batch timing constraints of vacuum coating systems. The result is a manufacturing process that can deliver:

- Uniform thin-film coatings on complex lens and mirror geometries

- Consistent coating quality from part to part

- Efficient scale-up from R&D to production throughput

- Reduced material waste versus dip/spin methods

Whether you need a Lens Coating System for industrial optics or photoresist deposition on lenses and mirrors, Sono-Tek ultrasonic spray provides a practical, high-quality coating solution for modern optical manufacturing.