Aluminum Flux Brazing Systems for Paint F Flux Application

Sono-Tek ultrasonic flux coating systems provide precise, uniform application of NOCOLOK Paint F-Flux for aluminum brazing. Used in both new and retrofitted brazing lines, these systems deliver consistent flux deposition for radiators, condensers, evaporators, charge-air coolers, and other aluminum heat-transfer assemblies.

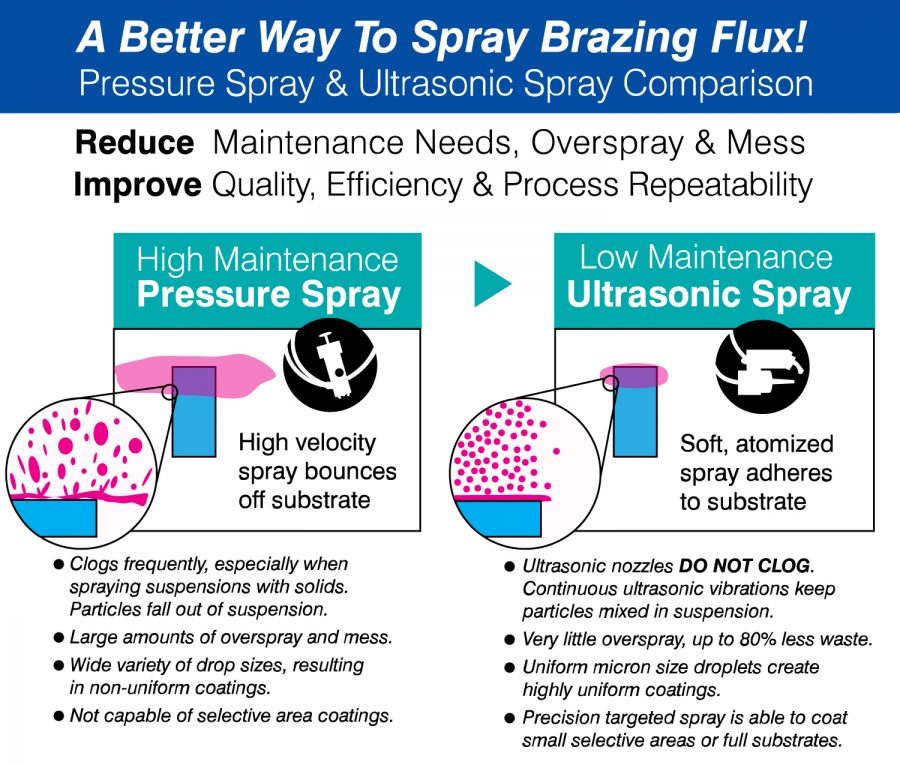

Ultrasonic atomization replaces high-waste pressure spraying with a controlled, enclosed process that improves brazing quality while drastically reducing flux consumption, downtime, and maintenance.

Visit How Ultrasonic Nozzles Work to learn more about the unique benefits of ultrasonic spray.

Ultrasonic Precision for Aluminum Flux Brazing

Ultrasonic nozzles generate a soft, controlled spray that distributes flux evenly across fins, tubes, and complex aluminum geometries. Continuous ultrasonic vibration maintains a homogeneous flux suspension, even when using water-based Paint-F-Flux formulations containing additives, binders, or fluorides supplied by manufacturers such as Solvay.

Adjustable spray width, flow rate, and nozzle selection allow precise control of:

- Flux layer thickness

- Targeted or wide-area coverage

- Flow stability and repeatability

- Adhesion and material usage efficiency

- Performance across a variety of flux carrier-system chemistries

This level of control supports high-quality brazing across a wide range of automotive and HVAC aluminum assemblies.

Applications for Paint F Flux and NOCOLOK Flux

- Radiators, evaporators, condensers

- Charge-air coolers

- Microchannel assemblies

- Fins, tubes, baffles, and folded structures

- Heat exchangers for automotive and HVAC markets

Benefits of Sono-Tek Ultrasonic Flux Brazing Systems

- Reduced flux consumption compared to pressure spraying

- Predictable, uniform flux deposition

- Enclosed process reduces drying and contamination

- Non-clogging ultrasonic nozzles for reliable continuous spraying

- Compatible with Paint-F-Flux, NOCOLOK, and related flux chemistries

- Fast setup, easy operation, and simplified maintenance

- Ideal for 24/7 aluminum brazing production

- Retrofit-friendly for existing brazing lines and paint flux machines

- Supports modern water-based flux formulations

Proven Results

Manufacturers using Sono-Tek aluminum flux brazing systems report:

- Approximately 60% reduction in Paint-F-Flux usage

- Over 90% reduction in maintenance

- Elimination of daily nozzle clogging

- More uniform and repeatable flux patterns

- Lower downtime and improved overall brazing line throughput

These results demonstrate the efficiency and reliability advantages ultrasonic spraying brings to aluminum flux brazing operations.

System Options for Aluminum Flux Brazing

SonoBraze 215 Flux Brazing System: A complete, enclosed ultrasonic flux coating system with volumetric pumping, recirculation, mixing, touchscreen control, and support for one or two ultrasonic nozzles. Ideal for high-volume, high-precision Paint-F-Flux deposition.

SonoBraze ALIGN Flux Brazing System: A compact ultrasonic spray module designed to integrate with existing customer-supplied flux delivery equipment. Provides ultrasonic performance, material savings, and consistent deposition without requiring major line changes.

Ultrasonic Nozzle Options

• AccuMist – 6–40 mm spray width for precise or narrow application

• Impact – up to 150–180 mm for wider fin and tube coverage

• Extend – up to 240 mm for large or complex aluminum assemblies

These nozzle families accommodate a wide range of flow rates, viscosities, and carrier-system chemistries used in modern flux formulas.

Process Support and Integration

Sono-Tek’s Applications Engineering and field service teams assist with system integration, nozzle configuration, process optimization, and production startup to ensure consistent flux deposition and reliable brazing performance across demanding manufacturing environments.

Contact Sono-Tek for Flux Brazing Solutions to discuss your application or request technical guidance on selecting the best flux brazing system for Paint-F-Flux or NOCOLOK brazing processes.