Ultrasonic spray systems for high-performance textile coatings

Sono-Tek ultrasonic coating systems are used to apply advanced, high-performance textile coatings during manufacturing, primarily in R&D and pilot-line environments. Our technology is not aimed at standard textile coating for color, bulk saturations, or selective-area spraying. Instead, Sono-Tek systems are used to apply very thin, surface-level nano-layers that add functionality without changing hand feel, drape, or breathability.

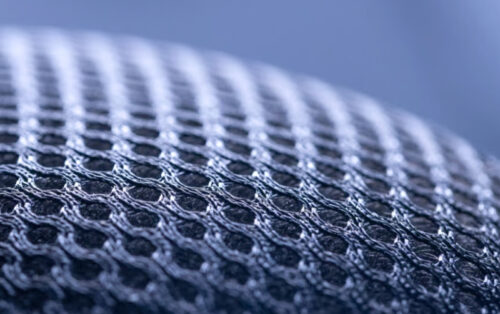

These high-precision textile thin film coating machines enable uniform nanoparticle deposition on textiles across wide webs with excellent repeatability. Large area textile coatings applied include: water and oil repellent coatings, antimicrobial coating on textiles, and anti-stain finishes. Uniform thin film layers of nanosuspensions or solutions are sprayed onto virtually any textile substrate—including woven and nonwoven materials—for medical textiles, flooring, carpeting, automotive, aerospace, and other industrial textile manufacturing applications.

These high-precision textile thin film coating machines enable uniform nanoparticle deposition on textiles across wide webs with excellent repeatability. Large area textile coatings applied include: water and oil repellent coatings, antimicrobial coating on textiles, and anti-stain finishes. Uniform thin film layers of nanosuspensions or solutions are sprayed onto virtually any textile substrate—including woven and nonwoven materials—for medical textiles, flooring, carpeting, automotive, aerospace, and other industrial textile manufacturing applications.

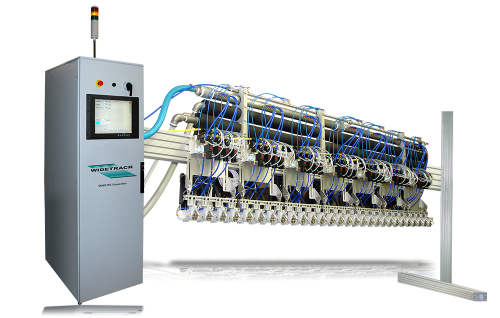

WideTrack textile finishing coating systems deliver dramatic reductions in water, chemical, and energy usage while producing high-quality, uniform coatings. Ultrasonic spray replaces inefficient dip or padding methods with a controllable, low-waste thin film coating process. WideTrack systems are designed to fully integrate as inline coaters within existing roll-to-roll manufacturing lines.

Ultrasonic Textile Coating System Benefits

- Retrofits into existing roll-to-roll manufacturing lines.

- Precise, repeatable, controlled deposition coatings for functional textile applications.

- Very small, atomized droplets with uniform particle sizes create consistent nanolayer thin film coatings.

- Non-clogging ultrasonic nozzle design reduces downtime for maintenance, even with viscosity-sensitive formulations.

- Dramatic savings in spray material, water and energy usage (up to 80% reduction).

- Soft atomized spray with very little bounceback provides a highly efficient coating process, unlike pressure spray or dipping methods.

- Environmental benefits from reduced overspray, reduced atmospheric release of coating material, and reduced or eliminated wastewater treatment.

Low Wet Pick-Up Spray Finishing

- 50–60% reduction in water.

- Substantial chemical reduction.

- Reduction in energy for drying and curing.

- Selective finishing of face/back of fabric.

- No dilution of solution with wet-on-wet finishing.

- Possibility of wet-on-wet finishing with two sequential sprays, while in dipping the fabric must be dried first.

- Possibility of applying two different finishes to each side (e.g. water absorption on one side and repellency on the other).

System configurations for advanced textile coatings

Systems for high-performance textile coatings are configured with either WideTrack or Impact spray heads, depending upon application requirements, target thin film thickness, and coating viscosity. Multiple nozzles are used to spray virtually any width with consistent uniformity across the entire substrate.

Our ultrasonic spray coaters have replaced pressure nozzles in a wide range of industrial and R&D textile industries. Companies striving to achieve sustainable, environmentally responsible manufacturing practices and limit unacceptable quantities of waste have adopted ultrasonic spraying as a coating technology that is more precise, more controllable, and more environmentally friendly than other application methods.

Next-Gen Textile R&D: Ultrasonic Nano-Layer Deposition and Plasma Integration

Sono-Tek ultrasonic spray platforms are widely used for next-generation textile development, where researchers are experimenting with emerging nano-materials and functional surface treatments. This is where ultrasonic spray excels: applying ultra-thin nano-layers on the outer surface of fabrics with high-precision control and minimal waste.

In addition to standalone ultrasonic coating, Sono-Tek systems are often integrated into hybrid finishing lines that include plasma textile coating or plasma surface activation. Plasma treatment increases textile surface energy and improves wettability and adhesion on difficult substrates, while ultrasonic spray applies controlled nanoparticle deposition on textiles as uniform thin film coatings.

These next-gen roll-to-roll R&D architectures support scalable development of advanced functions such as durable antimicrobial coating on textiles, repellency layers, conductive or sensing finishes, and other high-performance nano-coatings—providing a clear pathway to pilot-line production as materials and processes mature.

Visit How Ultrasonic Nozzles Work for more information about the unique benefits of ultrasonic spray coating.