Polyimide Coating Machine for Semiconductor Wafers

Sono-Tek ultrasonic polyimide coating systems deposit high-quality polyimide films onto the semiconductor wafer surface prior to dicing. These coating machines deliver excellent uniformity, precise thickness control, and strong adhesion for polymer and solvent-based coating materials used in semiconductor fabrication. The ultrasonic coating process provides a clean, efficient alternative to a spin coater, offering improved material efficiency and stable performance across both small-scale R&D work and production environments.

Sono-Tek’s polyimide product line is engineered for consistent wafer-level performance, helping manufacturers achieve repeatable film structure, optimal morphology, and controlled polyimide thicknesses ranging from sub-micron to multi-micron levels.

Ultrasonic Precision for Polyimide Wafer Coating

Ultrasonic spray coating provides a highly controlled method for depositing polyimide onto semiconductor wafers using curable polymer and solvent-based coating materials. This low-velocity spray process reduces overspray, improves edge definition, and ensures complete wafer coverage. The technology supports a wide range of modules and coating system configurations for different wafer sizes and coating diameters.

The ultrasonic coating process allows users to fine-tune:

- Polyimide coating thickness

- Coating diameter and full wafer coverage

- Droplet size and spray uniformity

- Adhesive or polymer layering behavior

- Solvent evaporation and drying conditions

- Micron-level films that maintain coating durability and semiconductor performance

This approach produces smooth, consistent, and durable polyimide coatings with far less material usage than traditional spin coater technology, while providing greater flexibility in film thickness and pattern control.

Typical Applications for Polyimide on Semiconductor Wafers

Sono-Tek coating systems support polyimide processes performed on the semiconductor wafer prior to dicing, including:

- Polyimide dielectric layers for semiconductor device fabrication

- Polyimide films used in redistribution layer (RDL) build-up

- Insulating or protective polyimide layers over photoresist and dielectric stacks

- MEMS wafer polyimide deposition

- Curable polymer coatings applied during wafer-level packaging and processing

All applications are performed at the wafer level before singulation, ensuring compatibility with clean-room semiconductor workflows.

Benefits of Sono-Tek Polyimide Coating Technology

- Highly uniform polyimide coatings across the entire semiconductor wafer

- Reduced polyimide consumption compared to spin coating methods

- Precise micron-level control of coating thickness and morphology

- Excellent adhesion on silicon wafers and advanced semiconductor substrates

- Stable, non-clogging ultrasonic performance for long run times

- Repeatable and programmable spray patterns for process consistency

- Clean, enclosed coating machine design suitable for semiconductor environments

- Compatible with a wide range of polymer and solvent-based coating materials

Polyimide Coating System Options

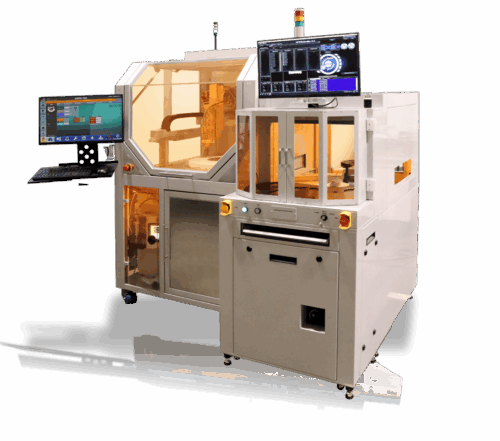

SPT 200

A precision ultrasonic coating machine designed for small scale semiconductor wafer processing and R&D. It provides adjustable coating diameter, controlled coating thickness, and reliable deposition for a broad range of polyimide and polymer formulations. The modular configuration allows adaptation to different process requirements within the product line.

SPT 200WS

An automated wafer-handling coating system engineered for higher throughput applications. The SPT 200WS supports cassette loading, wafer alignment, and consistent spray deposition for 100–300 mm wafers. Its automation modules enable reproducible polyimide film formation suitable for semiconductor production environments.

Both systems are optimized as polyimide coating machines for solvent-based and curable polymer coatings applied to semiconductor wafers before dicing.

Process Development and Application Support

Sono-Tek’s Applications Engineering team provides development support for polyimide coating processes, including optimization of evaporation behavior, coating diameter, spray patterns, and thickness targeting. Assistance includes integration of the coating system into clean room workflows and guidance for scaling from small scale R&D to larger production environments.

Contact Sono-Tek for Polyimide Coating Solutions – Discuss your application or request guidance on selecting a Polyimide Coating Machine, Polyimide Coating System, or Wafer Coating Machine configured for polyimide deposition on semiconductor wafers.