Ultrasonic Atomization – Precision Droplet Size and Advanced Ultrasonic Coating Technology

Innovation by Design: What Makes Ultrasonic Spray Nozzles Unique?

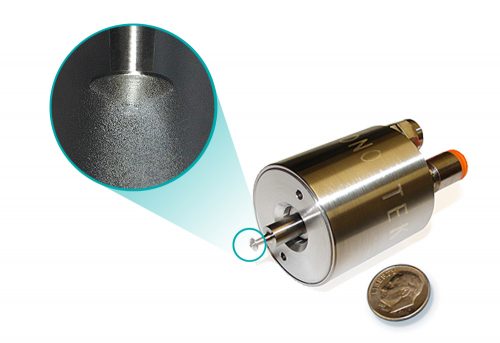

Sono-Tek ultrasonic spray atomizes liquids using high-frequency, piezoelectric transducers that convert electrical energy into mechanical vibration. These vibrations generate standing waves—an essential part of the atomization process—causing liquid to break into uniform fine droplets at uniform micron particle sizes.

Unlike conventional spray nozzles, ultrasonic nozzles do not depend on high pressure to force liquid through tiny orifices. Instead, the liquid passes through a comparatively large channel at very low flow rates, while the ultrasonic vibration (defined by resonant frequency and amplitude) creates consistent atomization. Power requirements remain extremely low, typically 1–8 watts per nozzle.

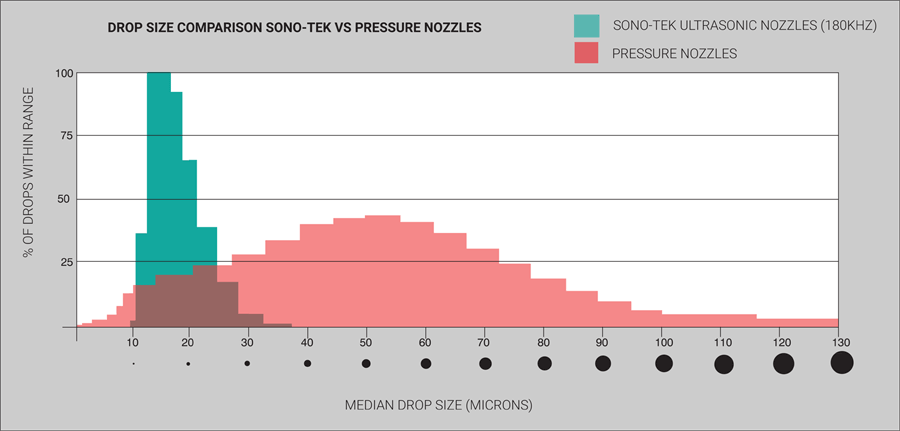

Tight drop distribution: Each ultrasonic nozzle operates at a resonant frequency that directly controls droplet size.

Droplet sizes have little variance, and can be mathematically calculated to fall within a tight predicted drop distribution that is much tighter than pressure nozzles.

• Example: 120 kHz → ~18 µm droplets for water

Higher frequencies produce smaller micron-scale droplets, while lower frequencies form larger ones. This frequency-driven atomization allows predictable, uniform, tight particle size distribution—critical for thin-film coating applications and consistent material deposition across any substrate.

Durable, Chemically resistant Materials of Construction

Sono-Tek nozzles are engineered from titanium and stainless steel for durability, acoustic performance, and chemical resistance. All wetted surfaces are titanium, with sealed internal components for contamination-free operation. There are no moving parts to wear out, and the continuous ultrasonic vibrations make ultrasonic nozzles non-clogging devices, contributing to very little maintenance requirements.

The liquid feed tube runs the entire length of the nozzle. The nozzle’s design ensures that liquid only comes into contact with titanium within the nozzle.

Click here to see a simple animation illustrating the atomization process.

Low-Velocity Fine Mist for Thin Film Coatings on Any Substrate

Low-Velocity Fine Mist for Thin Film Coatings on Any Substrate

Ultrasonic atomization produces a low-velocity fine mist that gently deposits onto the substrate, significantly reducing overspray and improving efficiency. This level of control is essential for thin film coatings, functional layers, and micro-scale coating applications.

With Sono-Tek’s patented air shaping, you can tailor spray patterns for any process geometry, including:

- Ultra-fine micro-lines (~0.4 mm)

- Small area fill patterns and selective area coatings

- Side walls and complex shapes

- Controlled conical patterns

- Wide, flat spray shapes

- Large-area coverage using multi-nozzle arrays

Learn more about spray shaping systems.

All of our coating systems incorporate one or more ultrasonic spray nozzles. Hundreds of different nozzle configurations are available. Integrated coating systems precisely regulate flow rate, positioning, exhaust, and process monitoring. R&D platforms such as ExactaCoat demonstrate precision ultrasonic spray behavior that easily scales into advanced industrial coating solutions and automated production lines. The same deposition benefits of our R&D scale coating systems are seen with large scale high volume systems.

Benefits of Ultrasonic Spray Coating Technology

Benefits of Ultrasonic Spray Coating Technology

- Up to 80% reduction in overspray and wasted material

- Uniform micron-level droplet size optimized for thin-film deposition

- Precise, repeatable spray patterns for micro- and macro-scale coating applications

- Titanium and stainless steel construction for long equipment life

- Ultra-low flow rate capability for advanced coating technology

- No moving parts—low-maintenance, non-clogging operation

- Predictable atomization driven by resonant frequency and amplitude

- Seamless scaling from R&D to pilot and high-volume coating systems

- Compatible with automated manufacturing lines and complex substrates

- Environmentally efficient operation with minimal overspray and energy use

Expanding Application Possibilities with Ultrasonic Spray Technology

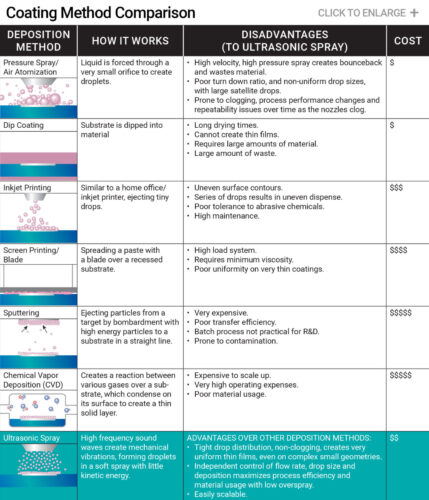

Ultrasonic spray technology enables coating processes that are difficult or impossible with traditional high-pressure spray nozzles. The combination of precise droplet size, low-velocity fine droplets, and controlled particle size distribution makes ultrasonic systems ideal for:

- Semiconductor wafer photoresist and polyimide coatings

- Fuel cell catalyst deposition and electrolyzer membrane coatings

- Medical device, pharmaceutical, and optical thin-film coatings

- Functional thin film coatings on glass, metal, textiles, ceramics, and plastics

- Printed electronics, micro-patterning, and precision coating applications

Non-Clogging Ultrasonic Atomizer with Stable Flow Rates

A major advantage of the ultrasonic atomizer is its inherently non-clogging design. The continuous high-frequency vibration prevents material build up, self-cleans, and maintains consistent spray performance—even with nanoparticle suspensions, catalysts, and some high-solids materials.

A major advantage of the ultrasonic atomizer is its inherently non-clogging design. The continuous high-frequency vibration prevents material build up, self-cleans, and maintains consistent spray performance—even with nanoparticle suspensions, catalysts, and some high-solids materials.

Ultrasonic energy keeps particles uniformly dispersed within the spray, ensuring even thin film formation and consistent particle size across the full substrate surface.

Across laboratory research, pilot development, and industrial high volume manufacturing, Sono-Tek ultrasonic spray systems deliver the highest level of precision and material efficiency available in precision coating technology, often enabling coatings that would otherwise not be possible.

Contact Us to Learn More About Sono-Tek Ultrasonic Coating Systems

Discover how ultrasonic spray nozzles and Sono-Tek coating systems can improve your coating performance through precise atomization, controlled particle size, optimized spray patterns, and low flow-rate thin-film deposition—across any substrate or application.