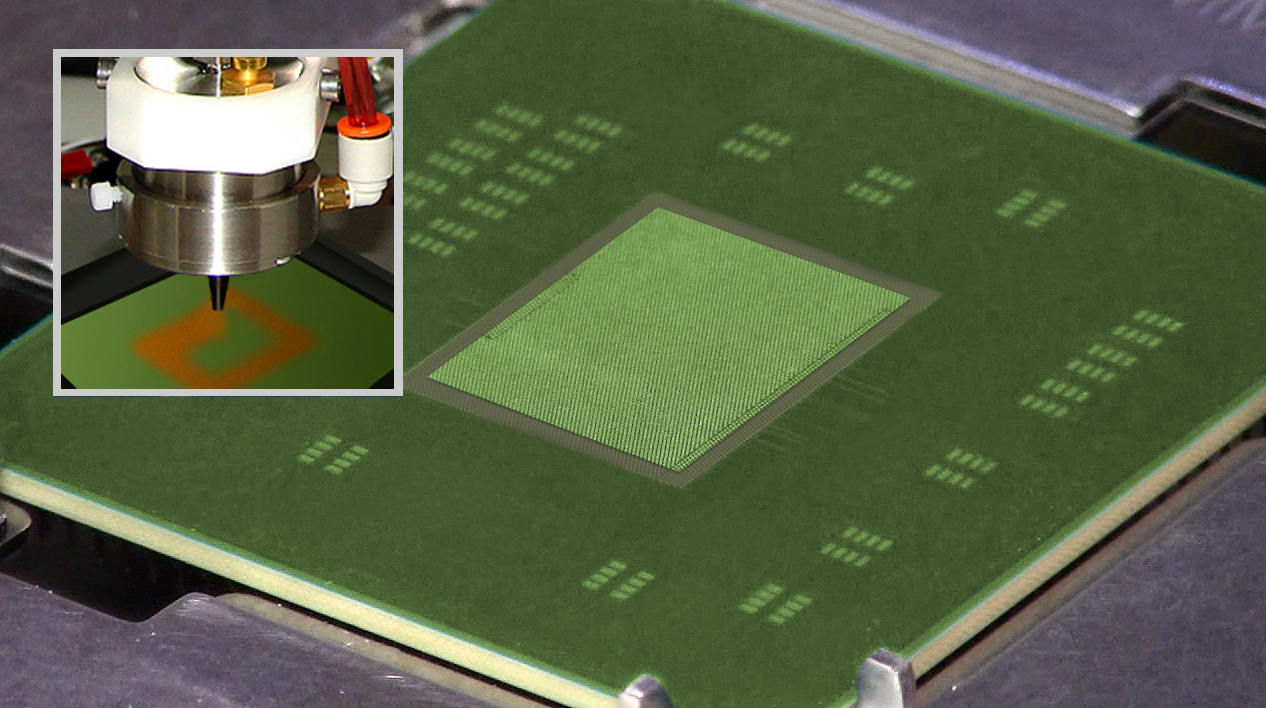

Precision spray fluxing for Flip Chip packaging processes

Sono-Tek is one of the originators of ultrasonic selective spray fluxing for PCBs, with extensive expertise applying highly uniform thin films of flux to targeted areas with little overspray and no clogging. Our 30 years of expertise in precision fluxing enabled us to develop the SelectaFlux Inline spray system for high volume Spray fluxing for flip chip applications. Ultrasonic spray provides a precise, repeatable, controllable solution for dispensing flip-chip flux onto contact pads and solder bump sites during advanced packaging.

The ability to spray very thin, uniform layers of flux prevents excessive flux residue, which can contribute to poor underfill and unreliable interconnections after reflow. Tight control of flux thickness also prevents die float, avoiding downtime and poor die-to-substrate connections. Minimal overspray prevents flux from contacting nearby passive devices and helps maintain clean, no-clean processing environments. Other methods such as jetting, dip fluxing, solder paste printing, and pressure nozzle spray cannot apply thin, targeted layers of flip-chip flux with comparable uniformity. High throughput is achieved with automated XYZ motion and conveyor capability for volume production. Multiple ultrasonic nozzle configurations are available to further speed the spray process. FlexiCoat is a proven production tool in flip chip packaging lines worldwide.

Benefits to using ultrasonic spray for Flip Chip packaging applications:

- Highly controllable spray avoids rework costs from overspray.

- Ability to control flux thickness, with coatings as thin as 20 microns.

- Uniform flux layer improves wetting and eliminates die float that can result in scrapping of the die and substrate.

- FlexiCoat coating system can receive JEDEC handling trays consisting of multiple substrate configurations.

- Non-clogging ultrasonic spray requires minimal cleaning and provides high repeatability, as spray performance is not compromised by gradual clogging experienced with pressure nozzles.

- Proven compatible with Indium flip-chip fluxes.