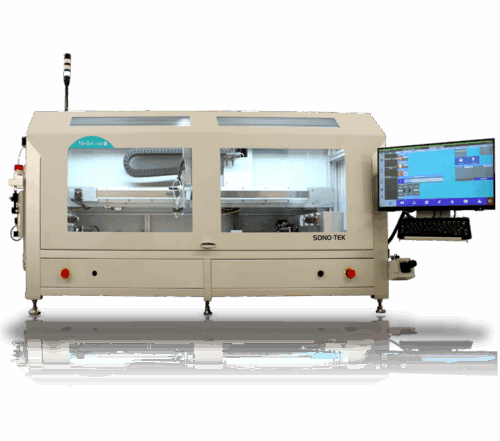

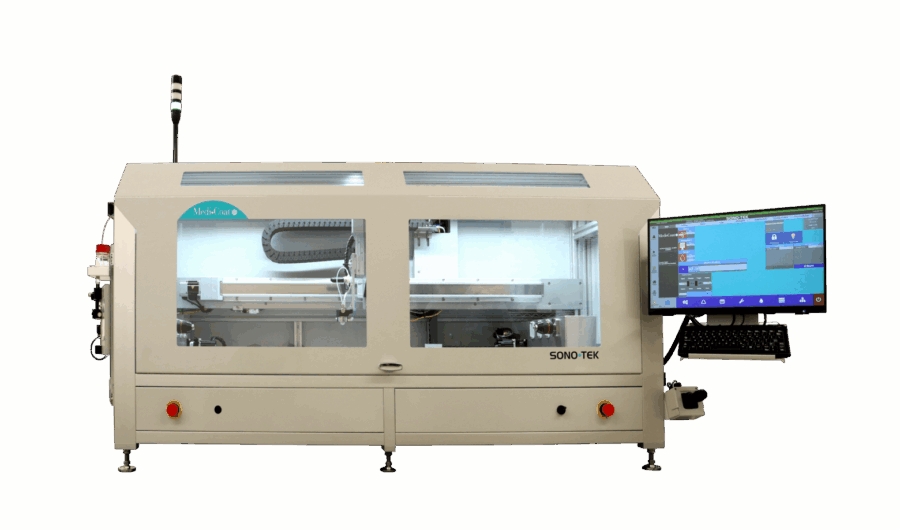

Ultrasonic Catheter Coating Systems

Sono-Tek ultrasonic catheter coating systems are purpose-built medical device platforms for precise, repeatable deposition of lubricious, hydrophilic, and functional medical device coatings on catheters, guidewires, and medical tubing. Each enclosed catheter coating machine provides uniform film thickness, excellent lubricity, and consistent coating quality across validated medical device manufacturing environments.

Compared with traditional dip coating, this ultrasonic coating technology delivers significantly tighter control of coating thickness and surface uniformity, particularly over long or complex geometries. Batch capability supports up to five catheters per cycle, making the platform practical for R&D, pilot builds, and low-volume production.

Technical Overview

The MediCoat CC1000 is a user-friendly catheter coating system that uses a precision AccuMist ultrasonic nozzle to atomize coating solutions into micron-scale droplets. The low-velocity spray produces thin, highly uniform layers with the ability to control coated length, surface morphology, and edge definition—critical requirements for multi-pass catheter builds and selective-area applications.

A programmable motion profile provides linear translation up to 1,000 mm and rotational speeds up to 400 RPM, supporting long substrates and complex geometries. The system can be configured for downstream drying or UV curing using integrated UV light where required by specific polymer chemistries or top coat performance targets.

Key System Parameters

- Nozzle type: AccuMist ultrasonic nozzle

- Spray pattern width: 2–10 mm

- Linear travel: 1,000 mm (single-axis)

- Rotational speed: Up to 400 RPM

- Typical median droplet size range: 18 µm (process dependent)

Advantages of Ultrasonic Spray for Catheter Coating

1. Precision Film Thickness and Coverage – Ultrasonic atomization enables consistent droplet generation that supports highly uniform, defect-free coatings. This level of control is critical for achieving repeatable catheter surface performance and consistent lubricity. Compared with dip coating, ultrasonic spray provides superior control of thickness and coverage along long shafts or complex features.

1. Precision Film Thickness and Coverage – Ultrasonic atomization enables consistent droplet generation that supports highly uniform, defect-free coatings. This level of control is critical for achieving repeatable catheter surface performance and consistent lubricity. Compared with dip coating, ultrasonic spray provides superior control of thickness and coverage along long shafts or complex features.

2. Controlled, Repeatable Coating Process – The ultrasonic nozzle produces a stable, low-velocity spray plume that improves coating uniformity and minimizes coating variability. This supports a reliable coating process for medical device coatings, from early feasibility through validated low-volume production.

3. Selective-Area and Multi-Layer Coating – A narrow spray pattern allows targeted application to specific regions, including defined coated length zones. The system supports sequential deposition of multi-layer structures—such as primer, functional layer, and lubricious top coat—with rapid drying or optional UV light curing between passes when compatible with the selected polymer. Example stacks may include a base layer plus a functional coating (antimicrobial, hemocompatible, or antifouling), followed by a lubricious hydrophilic top coat.

4. Process Optimization and Repeatability – Motion control parameters (translation speed, rotation rate, and spray flow) are fully programmable for rapid process development. The CC1000 delivers reproducible coating thickness and surface characteristics over extended use, supporting method transfer from R&D to pilot and low-volume manufacturing.

5. Practical Coating Equipment for R&D to Low-Volume Production – The MediCoat CC1000 is designed as flexible coating equipment that fits a wide range of development and early production needs. It can be configured for standalone laboratory operation or integrated into semi-automated catheter coating machines used in pilot and low-volume medical device manufacturing environments.

Applications

- Hydrophilic and lubricious shaft coatings for catheters and guidewires (including hydrogel or dry-lubricious top coat systems)

- Biocompatible and drug-eluting coatings for catheter-based delivery devices

- Selective functional coatings on tubing and small-diameter shafts

- R&D and pilot coating process development for antimicrobial / anti-biofilm catheter coatings (formulation-dependent)

- Development of hemocompatible / antithrombogenic coating layers for vascular catheter programs

- Zwitterionic or other antifouling hydrogel coatings in early-stage catheter R&D

- Multi-layer coating development and process scale-up

- Related programs in stents and other interventional medical device applications

- Drug-eluting balloon coating processes for catheter-based balloon systems (see Balloon Coatings)

Interested in ultrasonic coating machines for drug-eluting balloon catheters? Many balloon catheters require precise deposition of drug/polymer layers. Visit our Balloon Coatings page to learn about Sono-Tek systems designed specifically for drug-eluting balloon coating machines: https://www.sono-tek.com/industry/medical/balloons/

Summary

The MediCoat CC1000 ultrasonic catheter coating system provides a controlled, scalable coating machine platform for applying thin, uniform films to critical medical device components. By combining precision ultrasonic coating technology with robust programmable motion, it enables exceptional thickness control, repeatable lubricity performance, and reliable processing of advanced coating solutions for catheters and guidewires in R&D, pilot, and low-volume production settings.

Independent Research Using Ultrasonic Coating for Catheter Coatings: Ultrasonic coating technology has been used by academic researchers to apply thin, uniform antimicrobial coatings to catheter surfaces, with results published in peer-reviewed journals. Download the paper here: Antimicrobial efficacy of Ultrasonically deposited poly (vinl alcohol)/poly

(L-lysine)-based coatings for Urinary Catheters Surface & Coatings Technology – Elsevier https://www.sciencedirect.com/science/article/abs/pii/S0257897225013684