Blade Coating Machine for PTFE and Teflon Coating on Blades

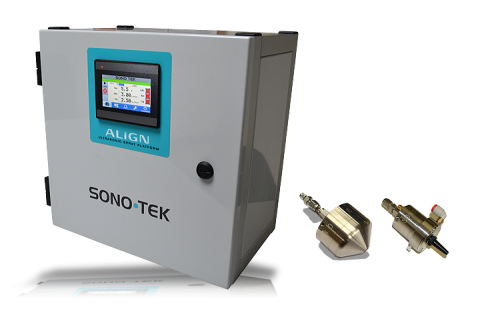

Sono-Tek ultrasonic spray technology provides a high-precision Blade Coating machine solution for applying lubricious and protective coatings in blade and surgical tool manufacturing. Ultrasonic spray functions as a controllable thin-film applicator, producing uniform micrometer-scale films on stainless steel and other blade substrates with minimal waste.

Sono-Tek ultrasonic spray technology provides a high-precision Blade Coating machine solution for applying lubricious and protective coatings in blade and surgical tool manufacturing. Ultrasonic spray functions as a controllable thin-film applicator, producing uniform micrometer-scale films on stainless steel and other blade substrates with minimal waste.

Ultrasonic coating systems are commonly used for PTFE Coating on Blades and Teflon Coating on Blades, as well as silicone and other low-viscosity lubricious coatings. These thin films improve durability and cutting performance, helping blades maintain a smooth, sharp edge for precise incisions while reducing tissue trauma. Staples for intestinal or vascular anastomosis can also be coated using the same ultrasonic film-coating approach.

High-Precision Thin-Film Applicator Performance

Ultrasonic spray is well suited to blade coating because it deposits consistent films measured in microns while allowing tight control of coating thickness and coating width. Compared with pressure spray and many conventional coating machines, ultrasonic atomization enables:

- Highly uniform film coating with micrometer-level control

- Precise, selective coating on blade edges, tips, or small features

- Minimal overspray and significant material savings (often up to ~80%)

- Non-clogging, low-maintenance nozzles that help reduce downtime

- Faster, more consistent curing due to thin, even layers

This combination supports sustainable manufacturing and reliable high-precision coating results.

PTFE / Teflon Coating on Blades for Lubricity and Durability

Applying a controlled PTFE (Teflon) surface layer to blades reduces friction, improves glide, and enhances wear resistance. Ultrasonic spray delivers an even PTFE film without flooding or pooling, making it ideal for coatings where consistent thickness in the microns range directly impacts cutting feel and long-term durability.

Typical applications include:

- Surgical blades and tools

- Microtome blades

- Medical and personal-hygiene shaving blades

Integration into Blade Manufacturing and Film-Coating Lines

Sono-Tek blade coaters are designed to integrate into existing production workflows as inline film coaters or stand-alone coating systems. Ultrasonic spray can be configured for multi-pass coating, patterned deposition, and narrow-track or wide-track coverage depending on product needs.

Methods such as doctor blade coating, slot-die coating, or slurry-based film coating are typically chosen when thick layers are required. For micrometer-thin, high-precision coatings on blades, ultrasonic spray is often the preferred approach because it delivers uniform thin films with excellent control and minimal waste.