Ultrasonic Spray of Molten Metals for Solder Powder Production

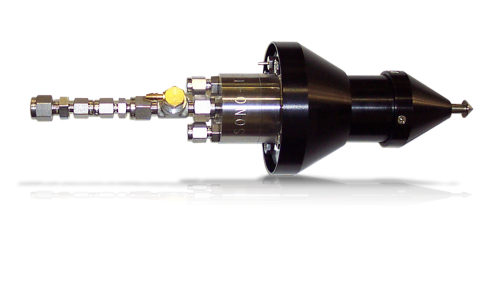

Sono-Tek’s MoltenMist is a specialized ultrasonic nozzle developed for Solder Atomization and other high-temperature Creation Metal Atomization processes. It produces uniform molten droplets that solidify into tightly controlled Solder Powder for downstream solder paste and electronics manufacturing. Precise particle size and powder size distribution are critical to consistent flux mixing, paste viscosity, printing behavior, and reliable SMT reflow results on printed circuit boards.

MoltenMist Nozzle Design for Production Environments

Ultrasonic nozzles are an effective tool for atomizing molten solder alloys, but traditional designs were limited in production by heat exposure and wear. MoltenMist overcomes these constraints with:

- Dual air/liquid cooling to protect piezoelectric transducers during high-temperature atomization

- A simple, replaceable atomizing surface for long runtime and stable solder powder output

- Consistent molten solder atomization in air, vacuum, or inert atmospheres to reduce oxidation

This design enables high-quality solder powder production without the thermal or durability limitations seen in earlier molten-metal ultrasonic systems.

Maintainability for Solder Alloys and Corrosive Melts

Molten solder alloy chemistries can be wear-prone or mildly corrosive to atomizing surfaces. MoltenMist uses a replaceable titanium atomizing tip, allowing fast restoration of performance when wear or corrosion begins to affect solder particle size uniformity.

High Throughput with Tight Particle Size Control

MoltenMist achieves high production flow by delivering molten solder through a feed tube positioned close to the atomizing surface. This supports both throughput and particle-size consistency needed for solder paste manufacturing and surface mount technology applications.

Typical capabilities include:

- Flow rates above 80 ml/min in air

- Flow rates above 100 ml/min under vacuum or inert atmospheres

- With SN63PB37 molten solder: approximately 680 g/min in air and 850 g/min under vacuum

The result is efficient solder powder generation with controlled particle size for repeatable soldering process performance, including wetting behavior, intermetallic formation control, and reliable SMT reflow on PCBs.