Functional Coatings on Glass for Advanced Performance and Nano-Thin Films

Sono-Tek ultrasonic spray systems enable precise, uniform application of functional coatings on glass across R&D, pilot-scale, and high-volume manufacturing environments. Our technology supports a wide range of functional glass coatings, including hydrophobic coatings, anti-reflection films, protective layers, anti-smudge treatments, and nanoparticle-enhanced thin films. Ultrasonic atomization produces high-quality film formation while minimizing overspray and solvent waste.

Sono-Tek ultrasonic spray systems enable precise, uniform application of functional coatings on glass across R&D, pilot-scale, and high-volume manufacturing environments. Our technology supports a wide range of functional glass coatings, including hydrophobic coatings, anti-reflection films, protective layers, anti-smudge treatments, and nanoparticle-enhanced thin films. Ultrasonic atomization produces high-quality film formation while minimizing overspray and solvent waste.

Whether developing a new nano-thin functional layer, engineering nanoscale interfaces, or scaling continuous coating onto large-format glass substrates, Sono-Tek provides glass coating solutions optimized for consistency, durability, optical properties, and production efficiency.

Ultrasonic Precision for Functional Thin Films on Glass

Ultrasonic spray deposition generates a controlled, low-velocity mist that forms smooth, uniform coatings while minimizing streaking, beading, and material waste. This method is ideal for nano-suspensions, sol-gel formulations, nanotechnology-driven materials, amorphous coatings, and other functional chemistries requiring gentle, highly controlled deposition onto glass surfaces.

By adjusting droplet size, spray passes, and flow rate, developers can optimize:

- Nano-thin and ultra-thin film thickness

- Surface performance such as hydrophobicity, clarity, and optical properties

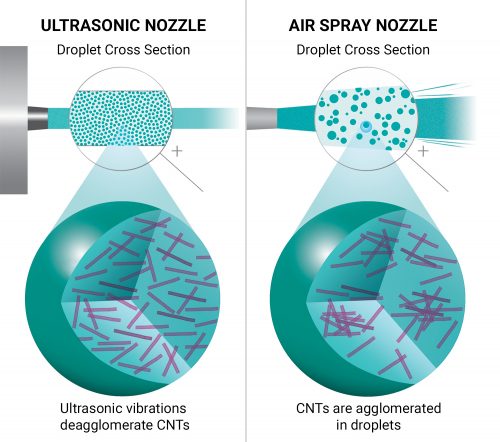

- Uniform nanoparticle dispersion that prevents agglomeration and ensures consistent film performance

- Adhesion, morphology, and nanoscale uniformity

- Functional interfaces for architectural, automotive, and specialty glass products

This level of precision supports advanced functionality for windshields, appliance glass, displays, and engineered glass components.

Typical Applications for Functional Coatings on Glass

Hydrophobic and Hydrophilic Surface Treatments: Nano-thin films that deliver easy-clean, anti-fog, and self-cleaning behavior for architectural, consumer, and automotive glass products, including windshields.

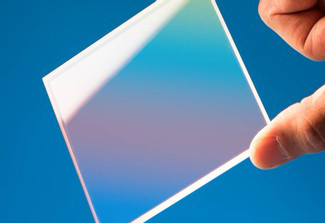

Optical and Anti-Reflective Films: Uniform thin films that improve light transmission, reduce glare, and enhance optical properties for display glass, lenses, and high-performance optical components.

Anti-Smudge and Protective Coatings: Functional coatings that improve abrasion resistance, fingerprint resistance, and long-term durability for touchscreens, appliance glass, and frequently handled glass surfaces.

Nanomaterial-Enhanced Functional Layers: Coatings containing nanoparticles, nanowires, or nanocrystals that modify surface energy, optical behavior, nanoscale structure, or other required functionality for engineered glass.

Benefits of Sono-Tek Ultrasonic Spray for Glass Coating Manufacturing

- Highly uniform, conformal coatings on small or large glass substrates

- Excellent material efficiency with reduced overspray and optimized solvent usage

- Non-clogging ultrasonic nozzles ideal for nanoparticle and sol-gel formulations

- Precise control of nano-thin and functional coatings with consistent repeatability

- Scalable coating systems for R&D, pilot-scale, and 24/7 industrial production

- Proven reliability for hydrophobic, optical, protective, and oxide-based coatings

- High versatility across a wide range of glass coating requirements

System Options for R&D, Pilot, and High-Volume Glass Coating

ExactaCoat – R&D Programmable Coating System

A flexible benchtop platform for developing and testing functional coatings on glass samples, featuring programmable XYZ motion, optional heated plates, and multiple ultrasonic nozzle configurations.

FlexiCoat – R&D to Pilot-Scale Coating System

A servo-driven, high-precision coating system with a large motion range and available heat/vacuum plates, vision alignment, and process integration modules. Ideal for nano-suspensions, sol-gel coatings, and functional layer development.

Industrial WideTrack Impact Ultrasonic Coating System

A production-grade ultrasonic system designed for continuous or semi-continuous coating of large glass panels. Provides wide-area uniformity, efficient material usage, and repeatable thickness control for demanding functional glass coatings.

Proven in Research and Production for Nano-Thin Functional Films

Extensive industrial and research use of ultrasonic spray deposition has demonstrated:

- Smooth, uniform nano-thin and nanoscale films using minimal coating solution

- Nano-structured, nanoparticle, amorphous, and sol-gel coatings with controlled morphology

- Deposition of optical, hydrophobic, and organic functional coatings

- Good adhesion and improved durability across architectural and specialty glass

- Thin-film characterization showing enhanced optical properties and stability

- Precise interface engineering for advanced optical materials and high-functionality glass products

These results highlight the versatility of ultrasonic spray coating for development, characterization, and high-volume production of functional coatings on glass.

Process Development and Application Support

Sono-Tek’s Applications Engineering Department provides guidance on system configuration, spray parameters, formulation compatibility, nanoscale characterization methods, and production integration. Our support helps customers achieve consistent, high-quality functional coatings across R&D, pilot, and full-scale manufacturing.

Contact Sono-Tek to discuss your glass coating application or request technical guidance from our Applications Engineering Department.