Anti-Microbial, Additive, and Barrier Coatings for Prepared Foods and Food Packaging

Sono-Tek ultrasonic food coating systems enable precise, uniform application of antimicrobial coatings, additives, and barrier coatings onto ready-made food products and food packaging. When food safety, controlled dosage, and thin-film uniformity matter, non-contact ultrasonic coating provides a highly repeatable coating process with minimal waste. Ultrasonic atomization creates a fine, gentle spray that supports anti-microbial coatings on food, polymer-based barrier layers, and thin deposition of oil for food products without flooding, pooling, or damaging sensitive surfaces.

Manufacturers use Sono-Tek systems to improve shelf life, reduce pathogens and microorganisms, and deliver scalable coating technologies compatible with GRAS formulations and modern clean-label requirements.

Anti-Microbial Coating Machine for Food Safety Coatings

Sono-Tek platforms are used as an Anti-Microbial Coating Machine for applying antimicrobial coatings on food in inline production. Ultrasonic spray supports uniform coverage of antimicrobial agents across complex food contact surfaces, helping suppress microbial growth from common foodborne illness organisms such as listeria monocytogenes, salmonella, e. coli, and other microbes.

Because ultrasonic nozzles generate a narrow droplet distribution with very low momentum, coatings can be applied as controlled nanolayers or micron-scale films—ideal for maximizing antimicrobial activity while minimizing additive usage. This uniformity is difficult to achieve with conventional pressure spray methods.

Typical antimicrobial coating approaches include:

- Thin films of antibacterial / antimicrobial coatings on prepared meats, cheeses, baked goods, produce, and other food products

- Application of enzymes, antioxidants, and other food science-backed preservatives where dosage accuracy is critical

- GRAS antimicrobial agents such as nisin or chitosan-based coatings for food preservation and public health support

Ultrasonic coating is especially valuable when processors need measurable food safety improvements without changing the base product formulation.

Chitosan and Biodegradable Antimicrobial Polymer Coatings

Many next-generation antimicrobial coatings rely on biodegradable polymers such as chitosan. Ultrasonic spray is well-suited for these slurries and polymer coating solutions because ultrasonic energy helps keep particles dispersed and avoids nozzle clogging, maintaining consistent coating morphology during long production runs.

In published work on food-packaging films, ultrasonic spray successfully deposited thin chitosan-based nanocomposite coatings with strong adhesion and uniform low-micron thickness. These coatings improved gas barrier performance while remaining compatible with sustainable, biodegradable substrates. That same capability translates into antimicrobial coatings on food and packaging where polymer uniformity and controlled incorporation of active agents drive performance.

Thin Deposition of Oil for Food Products

Sono-Tek ultrasonic systems are used for thin deposition of oil for food products such as baked goods, snacks, cereals, granola bars, and prepared items where light, uniform oiling prevents sticking, controls texture, or supports seasoning adhesion. Ultrasonic spray delivers controlled micro-droplet oils at very low flow rates, enabling consistent coverage without overspray or pooling.

Sono-Tek ultrasonic systems are used for thin deposition of oil for food products such as baked goods, snacks, cereals, granola bars, and prepared items where light, uniform oiling prevents sticking, controls texture, or supports seasoning adhesion. Ultrasonic spray delivers controlled micro-droplet oils at very low flow rates, enabling consistent coverage without overspray or pooling.

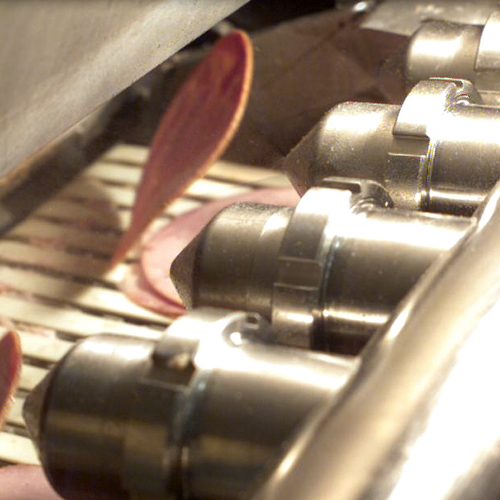

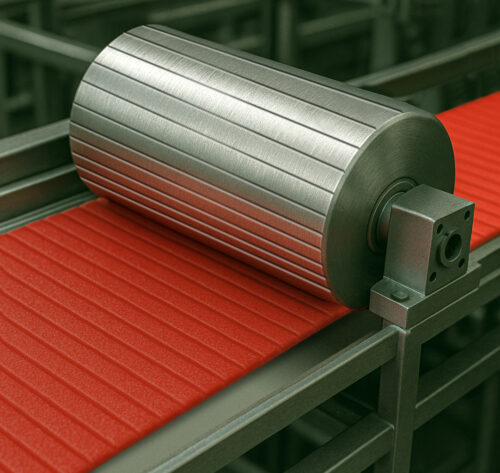

A common food industry application is candy manufacturing — including gum, licorice, and similar products — where a very thin, continuous oil film is applied onto rollers, belts, and other food contact surfaces that contact the candy. This light oil deposition prevents sticking during forming, pulling, and conveyance. Because the oil is applied precisely to the contact surfaces at extremely low flow, the process minimizes the amount of oil that transfers onto the candy product itself, helping manufacturers maintain texture, appearance, and clean labeling targets while improving line uptime.

Ultrasonic oil coating systems provide:

- Precise, uniform thin-layer coatings with minimal overspray

- Reduced oil usage and waste for cost-effective operation

- Proven continuous operation for production environments

- Easy integration into existing conveyor or roller-based lines, including wide-area processing

Because droplet size and flow rate are tightly controlled, oil coatings can be applied at extremely low levels while still achieving full, even coverage on both products and food contact surfaces.

Barrier Coatings for Food Packaging Materials

Barrier Coatings for Food Packaging Materials

Ultrasonic spray coating is increasingly used to apply polymer and nanocomposite barrier coatings onto packaging materials, including flexible films and biodegradable containers. These barrier coatings improve durability and shelf life by reducing oxygen and moisture transmission—critical for food packaging performance.

Technical studies show ultrasonic spray can deposit transparent, uniform barrier layers on biodegradable packaging films, significantly lowering oxygen and carbon-dioxide transmission compared with uncoated substrates. Ultrasonic coating technologies are attractive for packaging because they enable:

- Uniform thin-film polymer deposition without pinholes

- Controlled incorporation of nanoparticles or additives for enhanced barrier effect

- High transfer efficiency and low material waste

- Scalable coating process from food science R&D to production lines

Manufacturers exploring PFAS phase-out and sustainable packaging can use ultrasonic spray to apply next-gen biodegradable or water-based barrier layers without moving to costly multilayer laminate structures.

Why Ultrasonic Coating for Food Safety and Packaging?

Sono-Tek ultrasonic coating systems deliver major process advantages for antimicrobial and barrier coatings across the food industry:

-

- Uniform droplet distribution for repeatable antimicrobial activity

- Precise flow-rate control for consistent incorporation of additives

- Low-temperature, gentle spray that protects heat-sensitive foods and polymers

- Non-clogging nozzles for slurries, polymers, and nanosuspensions

- Easy scale-up to high-throughput coating equipment with multi-nozzle arrays

Talk to an Applications Engineer – Tell us about your food safety, antimicrobial coating, additive, or food packaging barrier project. Sono-Tek will recommend the right Anti-Microbial Coating Machine or SonoCoat coating platform, nozzle configuration, flow rate, and coating process to meet your targets for microbial control, shelf life extension, clean labeling, and cost-effective high-volume manufacturing.