Ultrasonic Spray Pyrolysis Systems for TCO and Functional Thin Films

Sono-Tek ultrasonic spray pyrolysis systems deliver precise, repeatable thin film deposition for transparent conductive oxides (TCOs), functional oxides, and emerging nanomaterials. Designed for R&D and pilot environments, these systems generate a uniform aerosol of fine droplets that convert into high-quality coatings at elevated substrate temperatures typical of spray pyrolysis (250–500 °C high-temperature processing).

Through highly controlled ultrasonic atomization, researchers achieve consistent film growth and reproducible morphology, enabling advanced development for solar cells, sensors, semiconductor coatings, and thin-film material studies.

Ultrasonic Precision for High-Temperature Thin Films

Sono-Tek’s low-velocity ultrasonic spray produces a finely controlled mist ideal for depositing precursor solutions that undergo thermal evaporation, decomposition, and conversion on heated substrates. The gentle spray minimizes overspray and maintains stable thermal conditions, improving the crystallinity, porosity, and surface area of resulting films.

By adjusting droplet size, flow rate, and spray pattern, researchers can tune:

- Film thickness and uniformity

- Microstructure and nanostructured morphology

- Optical and electrical properties

- Controlled growth of ZnO, SnO₂, ITO, FTO, CuInS₂, and complex oxide films

- Process behavior across glass, metal, and semiconductor substrates

Systems are compatible with aqueous, solvent-based, and metal-organic precursors used across TCO, photovoltaic, and functional oxide research.

Typical Applications in Research and Early-Stage Product Development Using Spray Pyrolysis

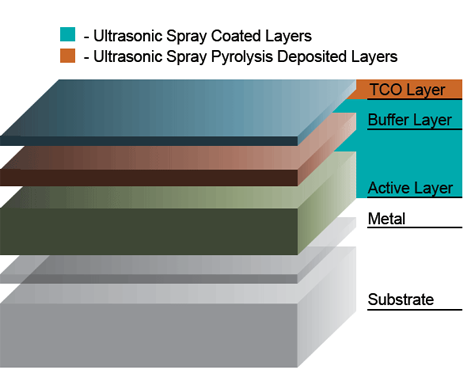

Transparent Conductive Oxides (TCOs): Uniform deposition of ITO, ZnO, SnO₂, and FTO for optoelectronic, electrochromic, and PV devices.

Gas Sensors and Functional Oxides: Nanostructured ZnO and SnO₂ coatings for high-sensitivity environmental and industrial sensing.

Solar Cell and Photovoltaic Absorber Films: CuInS₂ and organic layers including PEDOT:PSS and P3HT for next-generation solar cell studies.

Advanced Materials and Nanoparticle Synthesis: Spray pyrolysis synthesis of oxide powders, nanoparticles, ceramic particles, and engineered catalysts from controlled ultrasonic aerosols.

Benefits of Sono-Tek Ultrasonic Spray Pyrolysis Machines

Benefits of Sono-Tek Ultrasonic Spray Pyrolysis Machines

- Uniform, conformal thin films with precise thickness control

- Stable operation from 250–500 °C for pyrolytic conversion of precursor solutions

- Low-velocity spray minimizes overspray and maintains substrate temperature

- Non-clogging ultrasonic nozzles handle corrosive and high-solids chemistries

- High material utilization and repeatable deposition

- Scalable systems for R&D, pilot lines, and early production

- Compatible with aqueous, solvent, and metal-organic chemistries across oxide and nanomaterial development

System Options for R&D, Pilot-Scale, and Production Needs

ExactaCoat SC – R&D Ultrasonic Spray Pyrolysis Machine

A compact development platform with programmable XYZ motion, heated substrates up to 500 °C, and support for one or two ultrasonic nozzles for research-scale thin film growth.

Impact ARRAY – Pilot-Line and Early Production System

A modular, inline ultrasonic spray pyrolysis platform supporting multiple spray heads for wider-area coating and higher-throughput experimental work.

Proven in Scientific Research and Advanced Applications

Sono-Tek ultrasonic spray pyrolysis systems are widely referenced in peer-reviewed research (doi-indexed studies), including:

- Nanocrystalline ZnO gas sensor films with high surface area and enhanced sensitivity

- CuInS₂ absorber thin films with improved optical and electrical performance

- Organic photovoltaic layers (PEDOT:PSS, P3HT:PCBM) with finely controlled morphology

- Silver and zirconia nanoparticles synthesized from controlled ultrasonic aerosols

These studies demonstrate the versatility, reproducibility, and materials-engineering capabilities of ultrasonic spray pyrolysis.

Process Development and Application Support

Sono-Tek’s Applications Engineering Department provides guidance on system configuration, spray parameter optimization, thermal strategies, and material compatibility. The team assists researchers in achieving consistent coatings and optimizing thin film performance across nanomaterials, TCOs, and functional oxides.

Contact Sono-Tek for Spray Pyrolysis Solutions – Discuss your application with us or request technical support for thin-film spray pyrolysis, nanoparticle synthesis, or advanced material development.