Ultrasonic nozzles for spray drying spherical shape particles

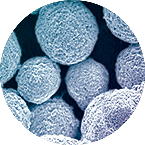

Sono-Tek’s ultrasonic spray drying technology produces exceptionally spherical, uniform particles with narrow size distribution and unmatched process repeatability.

This specialized ultrasonic spray drying nozzle is designed specifically for integration into BUCHI Spray Drying Systems, including the Ultrasonic Package for S-300 UL, and is also available for select direct applications and OEM collaborations.

To learn more or request a quote for integration with BUCHI systems, visit BUCHI’s Ultrasonic Package page or contact BUCHI directly.

Precision Atomization for Uniform Microcapsules and Powders

Sono-Tek’s ultrasonic spray drying nozzle is a purpose-engineered atomizer designed specifically for spray drying and microencapsulation processes — distinct from standard ultrasonic coating nozzles. Using high-frequency vibrations to produce exceptionally uniform droplets, this system enables precise control of particle size and morphology during drying or encapsulation.

Unlike conventional air pressure nozzles, which rely on high-velocity turbulence to break up liquid streams, ultrasonic atomization forms droplets through low-energy capillary waves formed inside the nozzle and dispersed at the nozzle tip. This gentle mechanism yields spherical, uniform droplets that dry into highly consistent, dense microcapsules — ideal for pharmaceutical, nutraceutical, and advanced materials applications.

BUCHI + Sono-Tek: Precision Spray Drying Partnership

Sono-Tek’s collaboration with BUCHI combines more than 40 years of ultrasonic atomization expertise with over 75 years of BUCHI’s leadership in laboratory spray drying systems. The result is a seamlessly integrated ultrasonic spray drying solution that delivers consistent, repeatable results for research and product development.

Advantages of Ultrasonic Spray Drying

Sono-Tek’s purpose-built ultrasonic spray drying nozzle is not adapted from coating systems; it is engineered specifically for spray drying, providing unique performance benefits:

- Tight droplet and particle size distribution with exceptional repeatability

- Highly spherical particle morphology, even for viscous or complex formulations

- Ability to produce larger, denser spheres compared to typical air-atomizing nozzles

- Virtually eliminates clogging, even with particle-laden or polymer-based feeds

- Gentle, low-shear atomization ideal for heat- or shear-sensitive materials

- Frequency-tuned droplet control (commonly 60 kHz) for adjustable particle size range

Applications

Ultrasonic spray drying with BUCHI and Sono-Tek technology is widely used in:

- Pharmaceutical and nutraceutical microencapsulation

- Protein and peptide formulation

- Food and flavor powders

- Functional materials, catalysts, and nanoparticles

- Academic and industrial R&D laboratories

Why Ultrasonic Atomization Produces Better Results

Peer-reviewed studies have shown that Sono-Tek ultrasonic nozzles produce smooth, spherical microcapsules and powders with uniform size and superior encapsulation efficiency, outperforming conventional air-blast and two-fluid spray drying methods.

The gentle, low-turbulence ultrasonic atomization process creates droplets that dry evenly into dense, reproducible spheres, free of the irregular or wrinkled morphologies common in traditional systems.

The following research paper includes discussion of Sono-Tek ultrasonic spray nozzles for in a microencapsulation application for drug delivery. https://link.springer.com/article/10.1007/s13346-023-01372-1

Learn More

For ultrasonic spray drying systems and retrofits, contact BUCHI or visit the

Ultrasonic Package for S-300 UL.