Uniform Thin-Film Solar Coatings with Ultrasonic Spray

Sono-Tek ultrasonic spray technology enables high-efficiency, highly uniform thin-film deposition for next-generation photovoltaic devices. As thin-film solar cells move from lab scale to commercial modules, manufacturers need coating methods that are scalable, repeatable, and cost-effective. Ultrasonic spray coating provides that bridge — delivering precise wet films over large substrate areas without the slow vacuum batch cycles of sputtering or CVD.

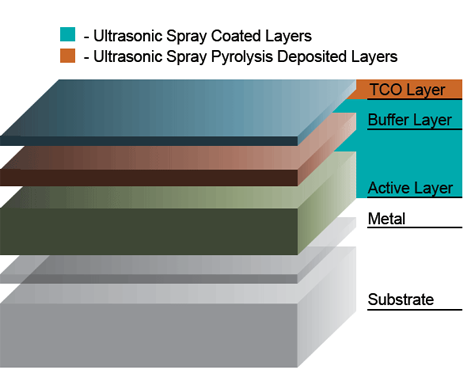

Ultrasonic spray is a proven platform for depositing multiple layers in thin-film solar cells, including transparent conductive oxide layers, buffer/organic layers, anti-reflection coatings, and especially the critical Perovskite Layer in perovskite and tandem devices.

Perovskite Coating System for Scalable Thin Film Solar Manufacturing

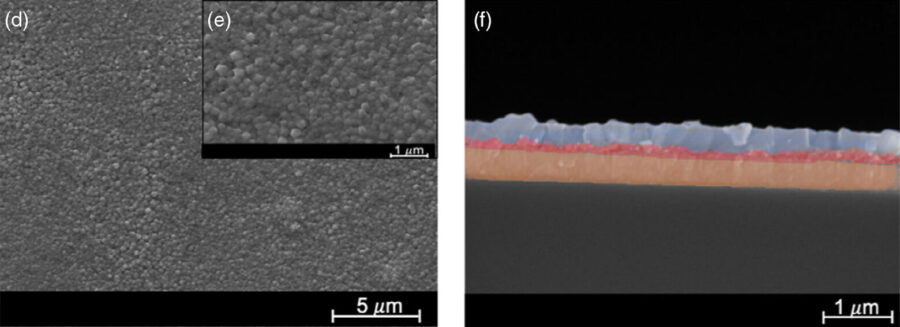

Photo: www.solar-rrl.com, Spray-Coated Lead-Free Cs2AgBiBr6 Double Perovskite Solar Cells with High Open-Circuit Voltage, 2021

Perovskites are among the most promising semiconductors for renewable energy, offering tunable bandgaps and compatibility with flexible substrates and tandem stacks. The main bottleneck has been translating high lab efficiencies into scalable manufacturing. Ultrasonic spray coating directly addresses that gap by depositing smooth, continuous wet layers in an automated, inline process.

Key advantages for a production-ready perovskite coating system include:

- Scalable coating of uniform Perovskite Layer and active layers over large substrates

- Inline, automated processing suited to Thin Film Solar Manufacturing

- Precise control of wet film thickness and morphology

- Excellent material utilization for expensive perovskite chemistries

- Compatibility with multi-pass or patterned deposition for advanced device architectures

Uniform Spray-Coated Perovskite Layer and Active Layers

Depositing a high-quality Perovskite Layer requires tight control of wet film formation, drying, and crystal growth. Ultrasonic spray coating produces smooth, uniform, pinhole-free perovskite films and supports repeatable layer builds needed for high-efficiency photovoltaic performance.

Benefits for perovskite and other active layers include:

- Precisely controllable, repeatable thin-film thickness

- Uniform coatings across large-area substrates

- High transfer efficiency to reduce precursor waste

- Gentle atomization for multi-component perovskite inks and polymer blends

- Inline compatibility for continuous production of solar panels and modules

Ultrasonic spray is also robust for complex or non-planar substrates, enabling new photovoltaic form factors beyond flat glass.

Spray Pyrolysis and Ultrasonic Spray Pyrolysis for TCO Layers

Transparent conductive oxide (TCO) layers are essential in many thin-film solar stacks. In some architectures they are deposited via Spray Pyrolysis — a high-temperature process that forms conductive films directly on a heated substrate. Today, Spray Pyrolysis and Ultrasonic Spray Pyrolysis are most often used in R&D and pilot-line environments, where they provide excellent flexibility for developing and tuning TCO and transport layers. The same fundamentals offer strong potential for scaling into inline manufacturing as processes mature.

Transparent conductive oxide (TCO) layers are essential in many thin-film solar stacks. In some architectures they are deposited via Spray Pyrolysis — a high-temperature process that forms conductive films directly on a heated substrate. Today, Spray Pyrolysis and Ultrasonic Spray Pyrolysis are most often used in R&D and pilot-line environments, where they provide excellent flexibility for developing and tuning TCO and transport layers. The same fundamentals offer strong potential for scaling into inline manufacturing as processes mature.

Sono-Tek systems support both conventional Spray Pyrolysis and Ultrasonic Spray Pyrolysis for layers such as:

- ITO

- ZnO (doped with Ga, Al, or In)

- CdO

- SnO₂

- CNTs / Silver Nanowires (AGNW) / Graphene

Ultrasonic Spray Pyrolysis benefits:

- Highly uniform high-temperature coatings on glass or flexible substrates

- Tight control of thickness for optical/electrical tuning

- Reduced defects compared with conventional pressure spray pyrolysis

- Clear scale-up pathway from bench tools to inline production systems

Thin-Film Solar Materials Sono-Tek Systems Support

Sono-Tek ultrasonic coating systems are used across a wide spectrum of thin-film photovoltaic chemistries:

Active Layers

- Perovskite Layer formulations (single-junction and tandem)

- OPV (organic photovoltaic) polymers and blends

- Quantum dots and nanocrystal semiconductors

- CIGS, CdTe, CZTS, and other thin-film absorber solutions

Ultrasonic spray keeps particles well-dispersed during coating, minimizing agglomeration and supporting uniform semiconductor films as processes scale from R&D to full-size modules.

Buffer / Organic Layers

- CdS and related buffer layers for CIGS / CdTe

- Organic transport layers and polymers such as PEDOT, PCBM, P3HT, P3HD, and related formulations

- Interface and passivation layers for improved device durability

Anti-Reflection Coatings

- SiO₂, TiO₂, and other AR formulations

- Optical layers designed to increase light capture and panel efficiency

Cost-Effective Alternative to Vacuum Deposition

Many thin-film solar layers can be deposited by sputtering, but vacuum tools are expensive, batch-oriented, and slower to adapt to new chemistries. Ultrasonic spray coating offers a cost-effective alternative or complement for solution-processed layers, particularly for perovskite active layers and hybrid stacks.

Why manufacturers adopt ultrasonic spray:

- Lower capital cost versus sputtering/CVD

- Inline, continuous processing instead of vacuum batch cycles

- High material utilization and reduced cost per watt

- Easy recipe adjustment for rapid R&D-to-production transfer

From R&D to High-Volume Thin-Film Solar Manufacturing

Sono-Tek systems are deployed worldwide in R&D, pilot lines, and production environments, helping customers validate coatings and then scale them into high-throughput thin-film solar manufacturing. Because ultrasonic spray is inherently modular, coating width and throughput can be expanded without changing the fundamental process physics — a key advantage for renewable energy scale-up.

Sono-Tek ultrasonic spray systems are used not only in R&D and pilot lines, but also in high-volume thin-film solar manufacturing by a leading global producer. This real-world production adoption demonstrates ultrasonic spray’s readiness for scalable photovoltaic manufacturing.

If you’re developing a new Perovskite Layer recipe, transitioning to Ultrasonic Spray Pyrolysis, or scaling any thin-film photovoltaic process, Sono-Tek provides the coating platforms, applications expertise, and process support to accelerate commercialization.

Peer-reviewed research published in ACS Applied Energy Materials demonstrates the use of Sono-Tek ultrasonic spray coating with an Impact nozzle to produce uniform, compact perovskite films for high-efficiency solar cells. Access the paper here: https://pubs.acs.org/doi/10.1021/acsaem.5c00718