Ultrasonic Fuel Cell Coating Technologies

Sono-Tek ultrasonic spray coating systems deliver high-quality, uniform fuel cell coatings for advanced energy manufacturing. Our coating technologies are used for PEM fuel cell, proton exchange membrane, and solid oxide fuel cell (SOFC) applications, as well as electrolyzers. Non-contact ultrasonic spray applies controlled catalyst and functional layers onto electrodes, anode and cathode substrates, and other fuel cell components, supporting repeatable coating processes from R&D through high-volume production. Our platforms are proven in high-volume fuel cell manufacturing environments, where consistent catalyst deposition and scalable throughput are critical for commercial success.

The Ultrasonic Advantage for Spray Catalyst and Nanosuspensions

Patented ultrasonic nozzle technology produces a soft, low-velocity spray with a tight droplet size distribution. Beyond atomization, the ultrasonic energy helps de-agglomerate nano-catalyst clumps back into separated particles before deposition. This keeps expensive precious-metal catalysts like platinum highly dispersed as they are coated, maximizing active surface area and coating efficiency on the electrode. The result is more uniform catalyst layers, higher catalyst utilization, and less waste compared with conventional spray and other coating technologies.

Ultrasonic spray patterns can be scaled from very small, precise coating footprints for R&D and prototyping to wide-area deposition for high-volume production, and multi-nozzle arrays support uniform coating of large-area substrates at high volume manufacturing scale.

PEM Fuel Cell and Proton Exchange Membrane Electrode Coatings

In PEM fuel cells, performance depends on consistent catalyst layers and ionomer distribution on the proton exchange membrane, gas diffusion layers (GDLs), and electrodes. Sono-Tek fuel cell coating machines provide precise spray catalyst deposition for:

- Anode and cathode catalyst layers on PEM electrodes

- Precious-metal catalyst coatings with controlled loading for cost-effective manufacturing

- Uniform coatings on sensitive PEM substrates without damaging the membrane

Ultrasonic spray supports controlled film build and morphology tuning so catalyst layers can be engineered for optimal porosity and transport. This enables high-performing PEM coatings that remain flexible and resist cracking during handling and operation, improving long-term durability.

Catalyst Coating Machine for Catalyst Deposition

Sono-Tek is an industry leader in Catalyst Coating Machine solutions built for catalyst deposition in fuel cells and electrolyzers. Ultrasonic spray enables:

- Accurate, repeatable deposition rates on electrodes and membranes

- High transfer efficiency for Spray Catalyst inks

- Minimal waste of high-cost precious metals

- Tunable coating solution delivery for optimized layer morphology and durability

Because ultrasonic action keeps nano-catalysts dispersed and prevents re-clumping, manufacturers can achieve uniform catalyst utilization at lower loadings, helping reduce total platinum usage per part while maintaining electrochemical performance.

Solid Oxide Fuel Cell Substrate Coating

Sono-Tek coating systems also support substrates of solid oxide fuel cells anode, cathode, and electrolyte-adjacent layers. Ultrasonic coating technologies can apply ceramic slurries, metal oxide suspensions, and functional coatings onto SOFC electrodes and other high-temperature substrates while maintaining uniformity. The soft ultrasonic plume improves adhesion on porous ceramics and complex geometries, supporting durable SOFC stack performance.

Systems to Suit Every Need: From R&D to High-Volume Production

Sono-Tek offers a complete line of fuel cell coating systems that scale smoothly from development to manufacturing:

- ExactaCoat FC tabletop systems for R&D and process optimization

- FlexiCoat OP3 FC for low-to-mid volume PEM and SOFC coating

- FlexiCoat FC and conveyorized platforms for mid-to-high volume catalyst deposition

- FC-INLINE and roll-to-roll / wide-area systems for custom designed continuous high-volume production

These coating systems use the same core ultrasonic nozzle technology, enabling consistent scale-up of coating recipes and performance.

The purchase of the SonoTek ExactaCoat and AccuMist Ultrasonic Nozzle has had a very important impact on membrane electrode assembly (MEA) fabrication procedures at PaxiTech. The ExactaCoat and AccuMist Ultrasonic Nozzle allowed us to increase our production capacity considerably and will also assist us in our technical preparation for a completely industrial automated MEA fabrication process… The change to SonoTek has improved MEA fabrication efficiency, productivity, precision and reliability without any loss in fuel cell performances.PaxiTech SAS – Grenoble, France

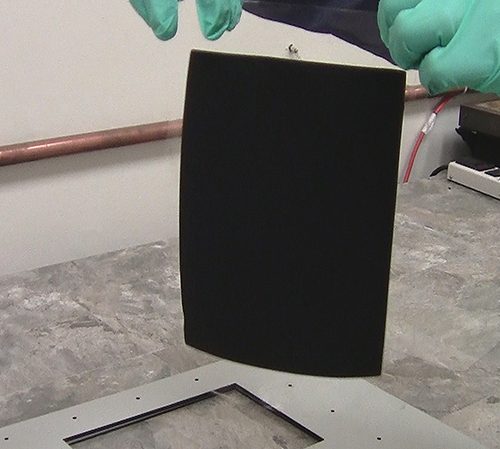

Precision, Porous Morphology, and Crack-Resistant Films

Fuel cell performance and lifetime depend on catalyst layers that are uniform, well-dispersed, and engineered for effective mass transport. Sono-Tek ultrasonic spray enables precise control of coating morphology, including porous microstructures that:

- Improve gas and water transport through the electrode

- Maintain flexibility of PEM catalyst layers

- Reduce cracking and delamination risk common with denser, less controlled coatings

- Support stable performance over long operating cycles

This morphology control, paired with ultrasonic de-agglomeration of nano-catalysts, helps maximize active catalytic area while preserving durability.

Process Options and Modular Add-Ons

Fuel cell coating machines can be configured with modular options to match your coating process and throughput goals, including:

- Heat plates for controlled drying

- Vacuum plates to secure delicate membranes and improve uniformity

- Dual nozzle configurations for layered chemistries or reduced cycle time

- Rod spinners and nozzle rotate/tilt options for SOFC and tubular substrates

- Precision liquid delivery for nanosuspensions and catalyst inks at low or high flow

These coating technologies help maintain consistent coating solution quality during long runs, supporting high-volume fuel cell manufacturing.

Proven Fuel Cell Coating Technology Worldwide

Sono-Tek fuel cell coating systems are used globally in both advanced energy research and high-volume production by premier fuel cell and electrolyzer manufacturers. This real-world manufacturing adoption demonstrates the scalability, reliability, and process repeatability of ultrasonic spray for catalyst deposition and MEA fabrication at commercial throughput. Our applications engineering team supports process development for PEM fuel cells, electrolyzers, and SOFC coatings, helping customers optimize catalyst deposition, porous morphology, and long-term durability for commercial production.

Sono-Tek ultrasonic nozzles break apart agglomerated particles as they travel down the nozzle body due to continuous ultrasonic vibrations along the length of the nozzle, resulting in the most effective use of functional particles. Breaking up agglomerates into evenly dispersed catalyst layers using ultrasonic spray results in higher electrochemical performance and greater repeatability of functional coatings.

Talk to an Applications Engineer – Tell us about your fuel cell or electrolyzer application. Sono-Tek will recommend the right Fuel Cell Coating Machine configuration, ultrasonic spray catalyst setup, coating process parameters, and production-scale coating systems to meet your targets for catalyst deposition, precious-metal efficiency, porous morphology, and durability.