Uniform thin film layers of functional nanomaterials

Sono-Tek ultrasonic nanomaterial coating systems are engineered for Nanomaterial Deposition of CNTs, silver nanowires (AgNWs), perovskites, graphene, quantum dots, and other advanced nanomaterials. By converting liquid suspensions into a soft, low-velocity mist, our technology delivers Thin Film Nanomaterials with exceptional uniformity on virtually any substrate, from small R&D coupons to roll-to-roll webs. Ultrasonic atomization also helps maintain stable nanoparticle dispersion during the coating process, supporting consistent nanoscale morphology and high-performance device results.

Why ultrasonic spray for nanomaterial deposition

Ultrasonic spray is a proven method for producing thin film coating layers where uniform dispersion and surface quality drive electrical conductivity, adhesion, and durability. In spray-coated CNT and polymer/CNT systems, rapid solvent evaporation helps prevent re-agglomeration and preserves homogeneous nanotube dispersion across the substrate. This enables repeatable nanostructures and controllable film thickness for electrodes, functional layers, and semiconductor devices.

Compared with spin or dip methods, spray deposition supports large-area uniform coatings and reproducible thin film morphology. Ultrasonic spray platforms are widely used to produce homogeneous, transparent conductive electrodes with low sheet resistance over large areas, reinforcing ultrasonic spray as a scalable nanowire coating approach for touch sensors, displays, and solar cells.

Nanotube deposition and deagglomeration advantages

Sono-Tek nozzles impart continuous ultrasonic energy directly at the point of atomization. This helps break apart soft agglomerates in CNT suspensions without damaging the nanomaterials, improving dispersion and minimizing clogging. The result is clean, stable nanotube deposition at low flow rates, ideal for precision thin film nanomaterials and high-performance semiconductor R&D.

Key benefits for CNT coating machine users include:

- Ultra-thin conductive coatings with tunable electrical conductivity and optical transparency

- Homogeneous nanoparticle coverage for maximum material utilization

- Gentle deposition that improves adhesion on polymers, glass, stainless steel, and flexible substrates

- Self-cleaning, non-clogging nozzle performance for reliable nanoscale spray runs

- Easy transition from benchtop characterization work to pilot and production coating systems

Nanowire coating systems for transparent electrodes

Silver nanowires and other nanowire networks are increasingly used as transparent electrodes in solar cells, advanced electronics, and flexible devices. Ultrasonic nanowire coating creates a uniform, percolating electrode structure while using less ink and enabling tighter control of film thickness and function. This makes ultrasonic spray a strong alternative to PVD and brittle TCO processes for nanowire electrode layers.

Applications commonly sprayed with Sono-Tek systems

Examples of nanotechnology applications where ultrasonic spray excels:

- CNT Coating Machine use for conductive films, EMI shielding, flexible sensors, and charge-transport layers

- Nanowire Coating System deposition of silver nanowires for transparent electrodes in displays, touch sensors, and thin-film solar cells

- Graphene and related nanomaterials for high-performance electrodes, protective coatings, and next-gen wearable or semiconductor structures

- Quantum dot and perovskite thin film coating for optoelectronics and solar cells

- Nanoparticle dispersions in polymer matrices for robust, durable nanoscale functional layers

From R&D characterization to scalable manufacturing

Sono-Tek platforms such as ExactaCoat, FlexiCoat, and custom roll-to-roll coating systems provide a clear pathway from lab-scale nanomaterial deposition to high-precision, wide-web production. Programmable motion, controllable droplet size, and stable dispersion handling make ultrasonic spray a flexible coating technology for researchers optimizing nanoscale morphology, spectroscopy-verified uniformity, and device-level performance.

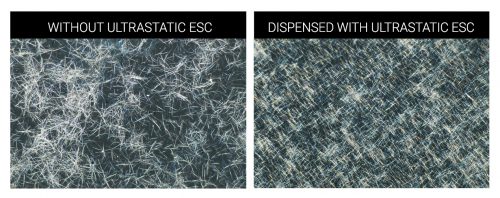

Ultrastatic ESC option for next-generation thin film nanomaterials

Sono-Tek has partnered with Sames Kremlin to develop Ultrastatic ESC (Enhanced Spray Coating), combining ultrasonic atomization with electrostatics. This hybrid nanomaterial deposition approach is offered as an R&D coater for laboratories exploring new thin film coating methods, especially where higher transfer efficiency, improved adhesion, or specialized nanostructure control are desired.

Other spraying techniques, in comparison, cannot disperse agglomerates, and clog easily. Read more information on the unique properties of ultrasonic spray nozzles.